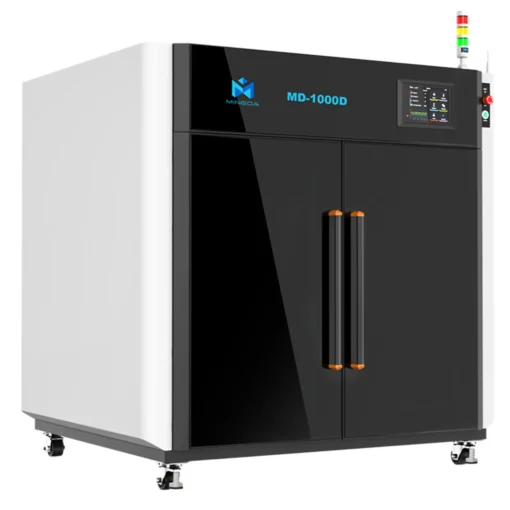

Is a high-performance industrial-grade 3D printer designed for large-scale and complex multi-material printing. With a massive 1000x1000x1000mm build volume and dual extruders, it allows for printing large prototypes, functional parts, and intricate models using a variety of materials. Featuring precise layer resolution, robust construction, and versatile filament compatibility, the MD-1000D delivers exceptional print quality and reliability for demanding industrial applications. Ideal for prototyping, product development, and custom manufacturing, this printer ensures consistent, high-quality results.

MingDa MD-1000D 3D

- Home

- Shop

- 3D printer, MINGDA 3D Printer

- MingDa MD-1000D 3D

MingDa MD-1000D 3D

- Description

Description

MingDa MD-1000D 3D features dual extruders, enabling multi-material printing for complex models

Features dual extruders for multi-material printing

MingDa MD-1000D 3D Printer is a high-performance, industrial-grade 3D printer designed for large-scale and multi-material printing applications. With an impressive build volume of 1000x1000x1000 mm, the MD-1000D is ideal for creating oversized prototypes, functional parts, and intricate models with precision and reliability.

3D Printer Materials Suitable for Your Applications

The hot end temperature can reach up to 350℃, allowing for the printing of engineering-grade materials such as carbon fiber, glass fiber, nylon composites, in addition to common materials

Common filament: PLA, TPU, PETG etc;

Engineering filament: HtPA, PET-GF, PET-CF, PA12-CF, HtPA-GF, HtPA-CF, HtPA-GF25,HtPA-CF25,etc

Support filament: S-Mulit, S-HtPA, etc

Get to Know the MD-1000D 3D Printer

High Accuracy at Fast Printing Speeds

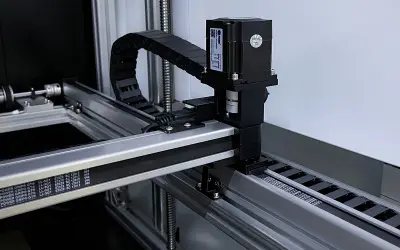

High Precision Using HIWIN linear rails structure and closed-loop motor design to ensure the stability and accuracy of the printing process Closed-loop Motors Using a closed-loop motor, it has fast response speed, no inertia and no delay. Closed-loop control overcomes the out-of-step problem. Heat and noise are significantly reduced. It enables printing models with ultra-high performance and speed.

Exceptional Stability in Long-time Printing

Customized CNC sheet metal integrated molding Ensures the stability of the machine, greatly extending its lifespan. High-quality profiles and hardware guarantee sustained and efficient operation of the machine. MINGDA 3D printers, developed since 2012, have been in operation for over 11 years, with each machine averaging over 35,000 hours of printing time, showcasing unparalleled stability.

Super Easy to Use

MINGDA OrcaSlicer MINGDA OrcaSlicer is a next-generation slicing software independently developed by us. All slicing profiles for materials have been rigorously tested and validated by our engineers within the MINGDA OrcaSlicer software. No parameter adjustments are needed before printing. Enjoy effortless, high-quality printing. Ready to Print Fully assembled and calibrated to its optimal state before leaving the factory. Upon receiving the machine, simply plug it in and start using it without requiring any prior experience

Remote Printing Multi-Machine Control

After being connected via WiFi or network cable, the MD-1000D can be remotely printed and monitored in real time. At the same time, it also supports multi machine control, facilitating rapid mass production.

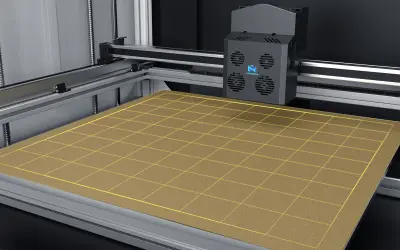

Hands-Free Auto Leveling

Making preparation before printing more convenient, Accurate first layer detection.

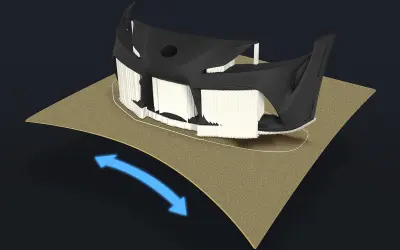

PEI Flexible Printing Platform

It has strong adhesion, high temperature resistance, and is suitable for various consumables. It can be easily removed by bending.

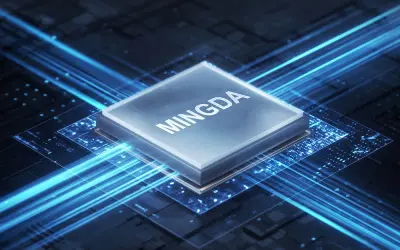

MINGDA Self-Developed Core Hardware

Delivers Speedy Smooth Performance. This high-performance 64-bit self-developed motherboard, powered by the 6-core CPU, ensures fast processing of data and rapid completion of 3D printing tasks. With 32GB of memory, you can quickly store, export, and print large files with ease.

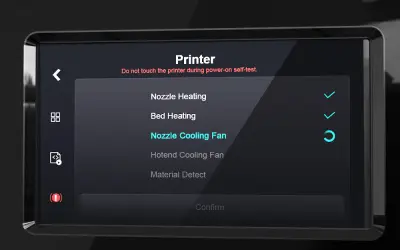

Self Check When Power On

When power on it can automaticly check the status of the extruder, hot bed, camera, automatic leveling, fan, and other components; if there are any abnormalities, a prompt will be displayed on the printer screen for quick and convenient processing.

Resume Printing and Filament Detection

The printer will automatically remember its current position and save printing data. In the event of a sudden power outage, it will lower the platform and retract the filament. Upon power restoration, it will resume seamless printing from the last stopping point. When filament runs out, the printer will stop printing and issue a warning to replace the filament, preventing wasted prints.

Product Parameters

| Parameter | Details |

|---|---|

| Model | MD-1000D |

| Print Technology | Fused Deposition Modeling (FDM) |

| Print Volume | 1000 * 1000 * 1000 mm |

| Machine Dimensions | 1680 * 1365 * 1665 mm |

| Extruder Type | Dual Extruders |

| Nozzle Diameter | 0.4mm (0.6, 0.8, 1.0 mm optional) |

| Max Extruder Temperature | ≤350°C (Recommended temperature ≤320 ℃) |

| Platform Temperature | ≤110°C |

| Max Flow | 40mm³/s |

| Max Print Speed | 500mm/s (Recommend Printing Speed: 200-300mm/s) |

| Support Software | MingDa OrcaSlicer, Prusa Slicer, etc |

| Display Screen | 10-inch HDMI touch screen |

| Input Voltage | 100/240AC 50/60Hz |

| Rated Power | 2700W |

| Firmware | klipper |

| Filament Compatibility | Common filament: PLA, TPU, PETG; Engineering filament: PET-CF/GF, HtPA-CF/GF, HtPA-GF25/CF25; Support filament: S-Mulit, S-HtPA, etc |