XLは、産業用途およびプロフェッショナル向けに、大型かつ高品質な3Dプリントを実現します。

Original Prusa XL ― 産業用途に最適な、大型・高精度印刷対応の3Dプリンターをぜひご体感ください。

- 説明

説明

This post is also available in: English (英語) ไทย (タイ語)

Original Prusa XL – 大型造形を実現する3Dプリンティングの革命

大規模プロジェクト向けの高性能3Dプリンター

Prusa XLは、広大な造形サイズと高品質出力を誇る、大型3Dプリント向けのプリンターです。産業用途にも適しており、精度とパフォーマンスを両立しています。

産業・プロフェッショナル向けの大型、高品質3D印刷を実現

Technical Parameters

| Measurements | |

|---|---|

| Build Volume | 360×360×360 mm (14.17’’×14.17’’×14.17’’) |

| Filament diameter | 1.75 mm |

| Layer height | 0.05-0.30 mm |

| Printer dimensions (without spool) | 27.9 kg (single-tool) / 29.3 kg (dual-head) / 33.7 kg (five-head), 700 mm (w) × 900 mm (h) × 720 mm (d) (27.5’’×35.5’’×28.5’’) including side spoolholders and the separate top enclosure cover |

| Electronics | |

| Mainboard | Custom 32-bit xBuddy electronics with STM32 |

| Stepper Drivers | Trinamic 2130 |

| Stepper motors | 1.8° |

| Extruder | |

| Extruder | Nextruder, Direct Drive, E3D V6 compatible (with adapter) |

| Extruder electronics | Custom breakout board for connecting fans, thermistors and other parts. |

| Filament path | Aluminum heatsink, all-metal hotend |

| Drive system | Nextruder Planetary Gear System, 10:1 gearbox ratio |

| Nozzle | |

| Max nozzle temperature | 290 °C / 554 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| Controls | |

| LCD screen | 3.5″ graphic 65k color screen |

| Connectivity | NFC receiver, optional ESP Wi-Fi module (delivered with the printer) |

| Print medium | USB drive / LAN / internet via Prusa Connect |

| Sensors | |

| Advanced sensors | Filament sensor, Loadcell sensor, Power panic, 4 high-precision thermistors (genuine Semitec) + fan motors RPM monitoring |

| Print surface | |

| Print surface | Segmented heatbed with 16 individually controlled segments, removable magnetic steel sheets with different surface finishes |

| Calibration | |

| Bed calibration | Automatic, Mesh Bed Leveling (only on print area) |

| Materials | |

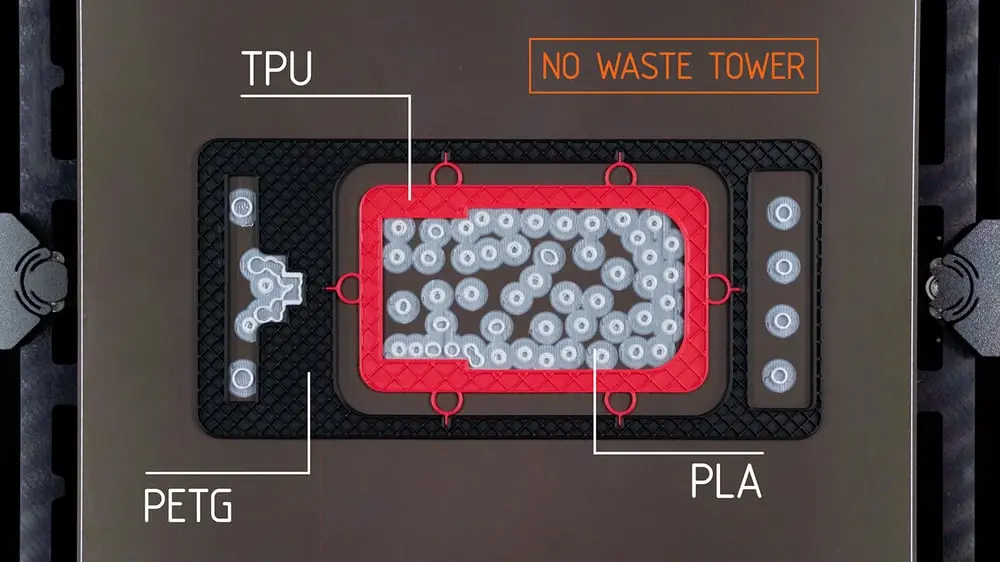

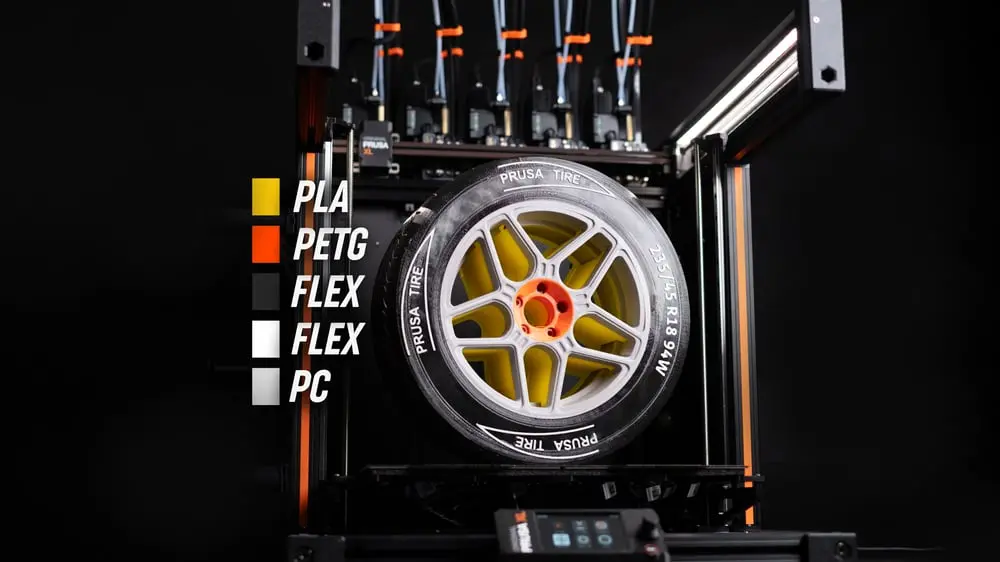

| Supported materials | PLA, PETG, Flex, PVA, PC, PP, CPE, PVB and when using the Original Prusa Enclosure with filtration add-on ABS, ASA, HIPS, PA |

| Power | |

| PSU | 240W, custom made by Delta with Power Panic HW |

| Power consumption | PLA settings: 80W / ABS settings: 120W |