3D Printing Serivces

Septillion Co., Ltd.2024-11-07T17:26:59+07:00This post is also available in: ไทย (Thai) 日本語 (Japanese)

Transform Your Ideas into Reality with Our Professional 3D Printing Services

Our 3D printing service offers cutting-edge solutions across various technologies, including FDM, SLA, SLS, and DMLS. Whether you need durable prototypes, complex geometries, or high-precision parts, we have the expertise and materials to bring your vision to life.

- FDM (Fused Deposition Modeling): Ideal for rapid prototyping and functional parts using durable thermoplastics.

- SLA (Stereolithography): Perfect for high-detail models with smooth finishes, suitable for detailed prototyping and design verification.

- SLS (Selective Laser Sintering): Excellent for creating strong, functional prototypes with complex structures, using durable nylon powders.

- DMLS (Direct Metal Laser Sintering): Advanced metal printing for precise, strong components with complex geometries, ideal for aerospace, automotive, and medical applications.

Our team ensures high-quality results tailored to your specifications, from prototype to production. Get in touch today to explore how our 3D printing services can elevate your projects!

PLA

ABS

PETG

PP

PC

NYLON

TPU

HIPS

Fused Deposition Modeling

Fused Deposition Modeling (FDM) is a popular 3D printing technology that uses thermoplastic filaments to create precise, durable parts layer-by-layer. Ideal for rapid prototyping, FDM is widely used across industries for its reliability, accessibility, and range of material options, including ABS, PLA, and nylon.

Advantages of FDM 3D Printing:

- Cost-Effective: Affordable for both prototyping and low-volume production.

- Material Variety: Supports various thermoplastics with different properties.

- Durability: Produces strong, functional parts for real-world applications.

- Ease of Use: User-friendly, suitable for both beginners and professionals.

FDM is perfect for creating functional prototypes, tooling, jigs, fixtures, and end-use parts for industries like automotive, aerospace, consumer goods, and engineering. It’s also widely used in educational settings for teaching and experimentation due to its accessibility and safety.

Our FDM 3D printing service provides high-quality, consistent results, whether you need a simple prototype or complex, functional components. Reach out to learn how FDM can bring your designs to life!

Stereolithography

Stereolithography (SLA) 3D printing uses a laser to cure liquid resin layer by layer, creating models with remarkable precision and smooth surface finishes. Known for its high-quality results, SLA is ideal for applications where accuracy and detail are paramount.

Advantages of SLA 3D Printing:

- High Precision: Achieves intricate details suitable for complex designs.

- Smooth Surface Finish: Perfect for presentation-ready prototypes.

- Wide Material Range: Supports a variety of Formlabs resins, such as Tough, Elastic, and BioMed for specialized needs.

SLA printing is commonly used in industries requiring precise prototyping, dental and medical applications, and functional parts. Formlabs printers, such as the Form 3 and Form 4, deliver professional-quality prints with versatile material options, making them ideal for healthcare, engineering, and design projects.

Standard Resin

Engineer Resin

Dental Resin

Medical Resin

Jewelry Resin

PA 11

PA 11 CF

PA 12

Pa 12 GF

PA 12 Tough

PA 12 White

TPU

PP

Selective Laser Sintering

Selective Laser Sintering (SLS) 3D printing uses a laser to fuse powdered materials layer by layer, creating strong, durable parts without the need for support structures. SLS is ideal for applications that require functional prototypes and end-use parts with complex geometries.

Advantages of SLS 3D Printing:

- High Durability: Creates robust parts suited for functional testing and production.

- Complex Geometry Capabilities: Enables intricate designs without support structures.

- Material Versatility: EOS and Formlabs offer advanced powders like Nylon 12, Nylon 11, and TPU for specific applications.

SLS is widely used in industries such as automotive, aerospace, and medical for producing functional prototypes, custom tooling, and even low-volume end-use parts. With high-quality printers like the EOS P Series and Formlabs Fuse 1+, companies can produce consistent, reliable parts for demanding applications.

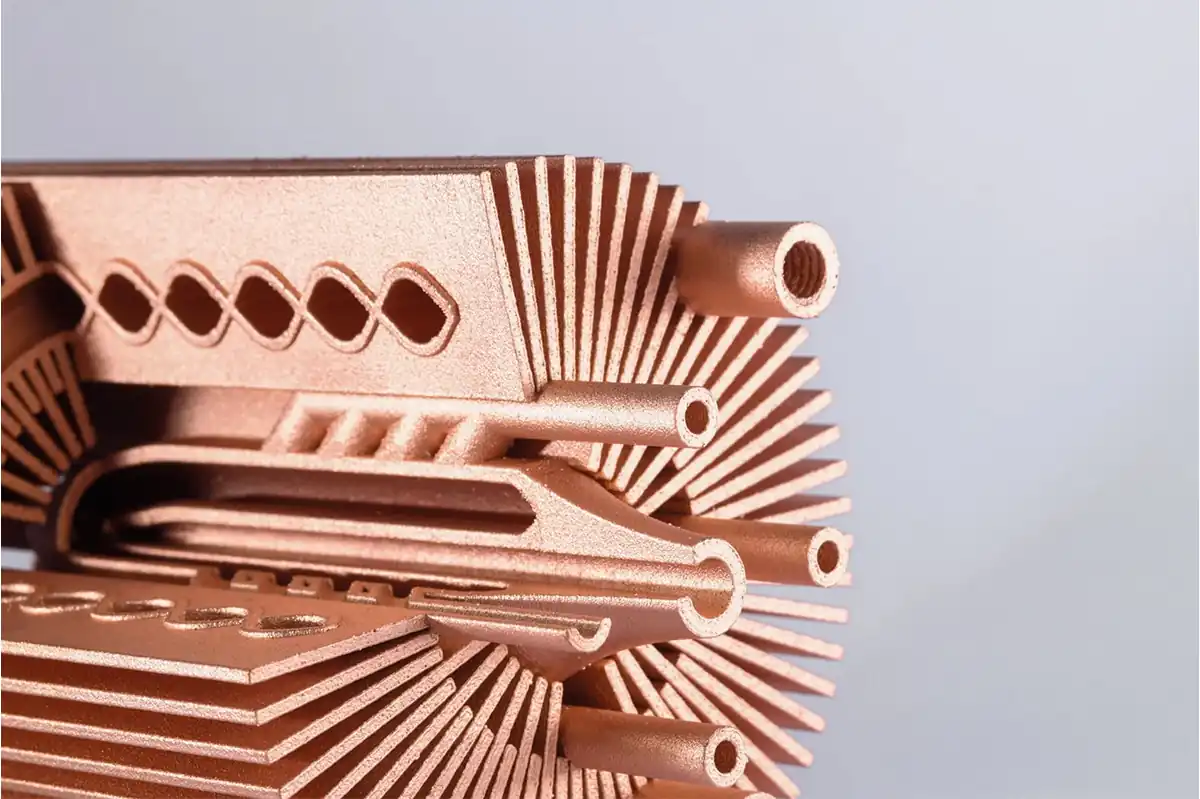

Direct Metal Laser Sintering

Direct Metal Laser Sintering (DMLS) is an advanced 3D printing technology that uses a high-powered laser to sinter metal powder, layer by layer, to create precise, fully dense metal parts. DMLS is perfect for producing complex geometries and high-performance components, commonly utilized in industries like aerospace, automotive, and medical.

Advantages of DMLS 3D Printing:

- High Precision: Ideal for intricate designs that traditional manufacturing can’t achieve.

- Strength and Durability: Produces metal parts with properties similar to wrought materials.

- Material Range: EOS offers various materials such as aluminum, titanium, and stainless steel for specific industrial needs.

DMLS is commonly used for aerospace parts, medical implants, and custom automotive components. With EOS printers, manufacturers can achieve repeatable quality and performance, making it an ideal choice for applications that demand high reliability and strength.

Aluminium

Case Hardening Steel

Copper

Nickel Alloys

Stainless Steel

Titanium