3D Systems DMP Factory 500

- Home

- Shop

- 3D printer, 3D Systems 3D Printer, Metal 3D Printer

- 3D Systems DMP Factory 500

3D Systems DMP Factory 500

DMP Factory 500 is a large-scale industrial metal 3D printer offering high precision and productivity.

Discover 3D Systems DMP Factory 500 – large-scale, high-performance metal 3D printing for industrial mass production.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

3D Systems DMP Factory500 – Industrial DMLS 3D Printer

Large-scale, high-performance metal 3D printing for mass production

The 3D Systems DMP Factory500 is engineered for large-scale metal 3D printing, delivering exceptional precision and efficiency.

It’s ideal for industries looking for large-volume, high-quality metal parts.

Modularity for a Scalable Factory Solution

The DMP Factory 500 is comprised of function-specific modules designed to maximize efficiency by optimizing utilization. Each module within the factory solution is fully integrated with a Removable Print Module (RPM) which is vacuum sealable for a controlled print environment and engineered to move between printer and powder modules for continuous production workflow.

Printer modules (PTM) are designed for ongoing, 24/7 printing of parts. The Depowdering Module (DPM) and Powder Recycling Module (PRM) are designed to efficiently depowder parts on build platforms and automatically recycle unused powder materials to prepare the RPM for the next build. A DMP Build Changeover Station (BCS) can be utilized to turnover a printing module from one build to the next and can effectively serve two DMP Factory printers that are running different materials.

Configure your factory setup with the optimum number and type of modules you need to meet your production workflow needs. Click the link below to watch “How-To” videos on using DMP Factory 500 and its modules.

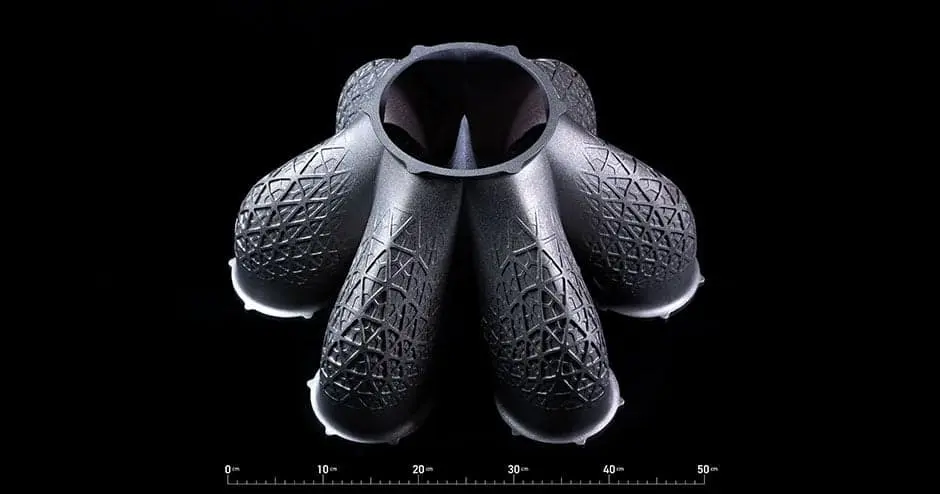

Seamless Large Parts

The intelligent laser configuration and 3DXpert software-driven scan technology of the DMP Factory 500 enable the production of seamless large parts the size of the full build volume (500mm x 500mm x 500mm). This results in the highest surface quality for metal 3D printed parts with outstanding material properties.

Uniform, Repeatable Quality

When it comes to production, repeatable part quality is essential. Featuring a vacuum chamber to ensure the lowest O2 content, the DMP Factory 500 printer module provides high-quality 3D printed metal parts. Powder degradation is eliminated by keeping the powder under inert conditions at all times, whether you are printing, depowdering, recycling, or transporting between modules.

High Productivity

With a large build volume (500 x 500 x 500 mm) and high throughput enabled by multiple lasers, the DMP Factory 500 delivers high productivity in metal additive manufacturing. Paired with its modular design, scaling production is straightforward through the installation of the additional metal printer and powder modules.

Metal 3D Printing with Lower Part Costs

The modular design of DMP Factory 500 enables the continuous function of all metal 3D printing and powder management modules to maximize uptime, throughput, and operational value.

The ability to match the number and type of modules required for your production workflow helps optimize your investment while minimizing manual processes further reducing ownership and operational costs.

Tech Specs

- Uses Direct Metal Printing (DMP) technology

- Build volume (W x D x H): 500 x 500 x 500 mm(20.7 x 20.7 x 20.7 in) – height inclusive of build plate

- Unique vacuum chamber concept (O2< 25ppm)

- Quick-swap removable print modules

- Fast bi-directional powder deposition