Apium M220

- Home

- Shop

- 3D printer, Apium 3D Printer

- Apium M220

Apium M220

Apium M220 specializes in printing high-temperature materials such as PEEK for industrial-grade applications.

Discover Apium M220 – The advanced 3D printer for high-temperature engineering polymers like PEEK, designed for industrial use.

- Description

Description

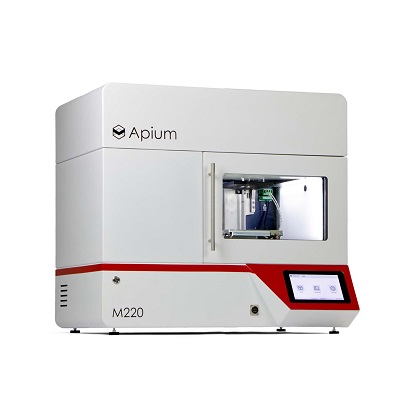

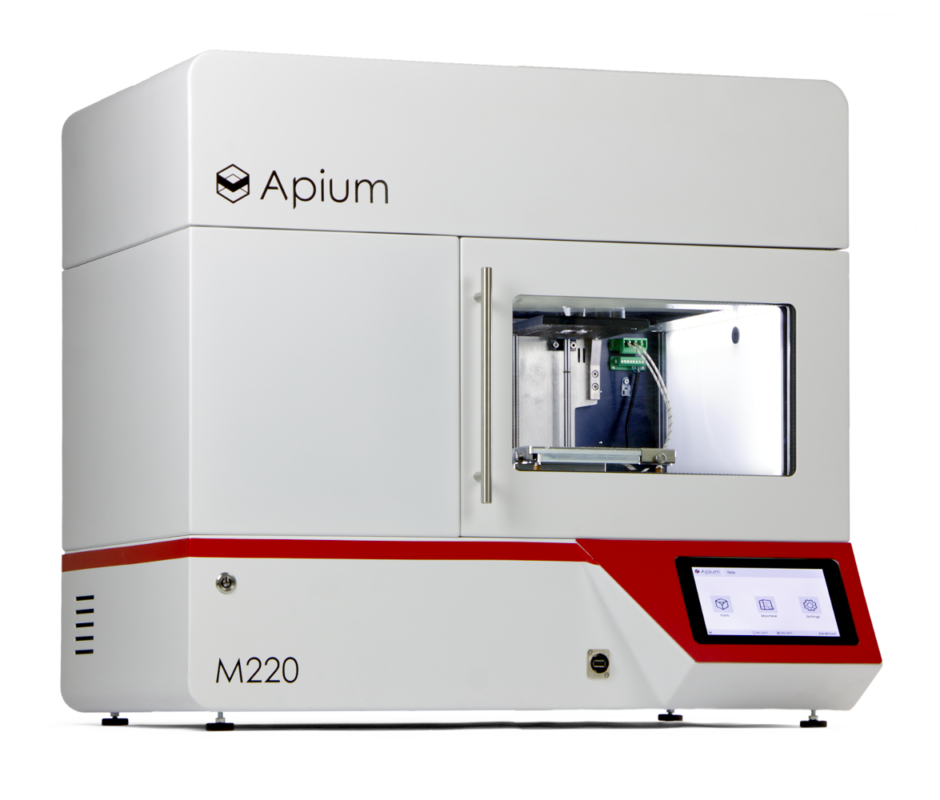

Apium M220 – High-Temperature 3D Printing for PEEK Materials

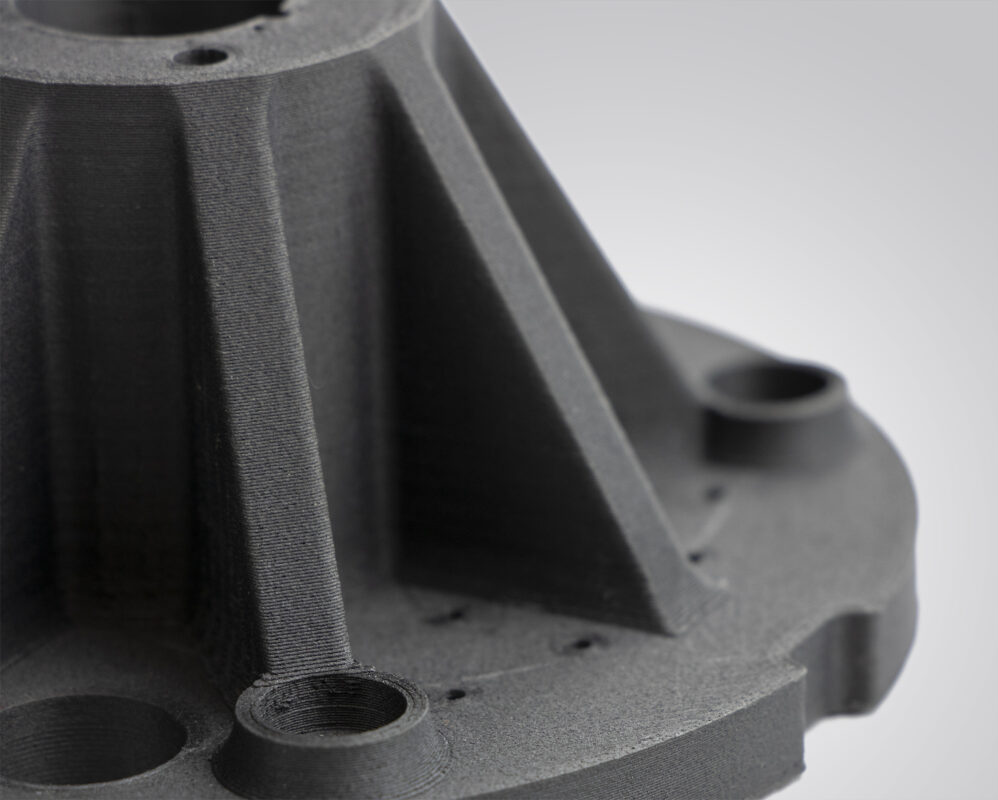

Precision printing with high-performance engineering polymers

The Apium M220 is designed for the precise 3D printing of high-performance materials like PEEK. It offers consistent quality,

ideal for demanding sectors such as aerospace, medical, and automotive industries.

Apium M220

Apium Provides a cost-effective solution to manufacture customized implants

The M220 is the world’s first 3D printer designed specifically for the manufacturing of medical products and implants made out of PEEK.

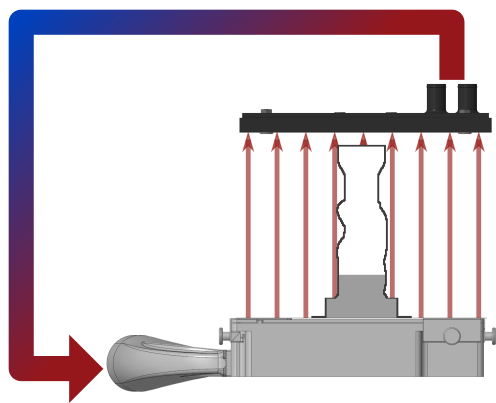

Sterile printing environment

The hot-air filter system analyses the component geometry and adapts the

heating power so that an optimum energy input is always achieved. The air flow enclosing the component is filtered in a practically particlefree circuit.

New extrusion technology

Our extruder was developed regarding flexibility and durability. The four

times higher feed force compared to the previous model enables a

precise material flow. All components in contact with the printing material

are made of medically compatible materials: PEEK, titanium, 316L

steel and PTFE.

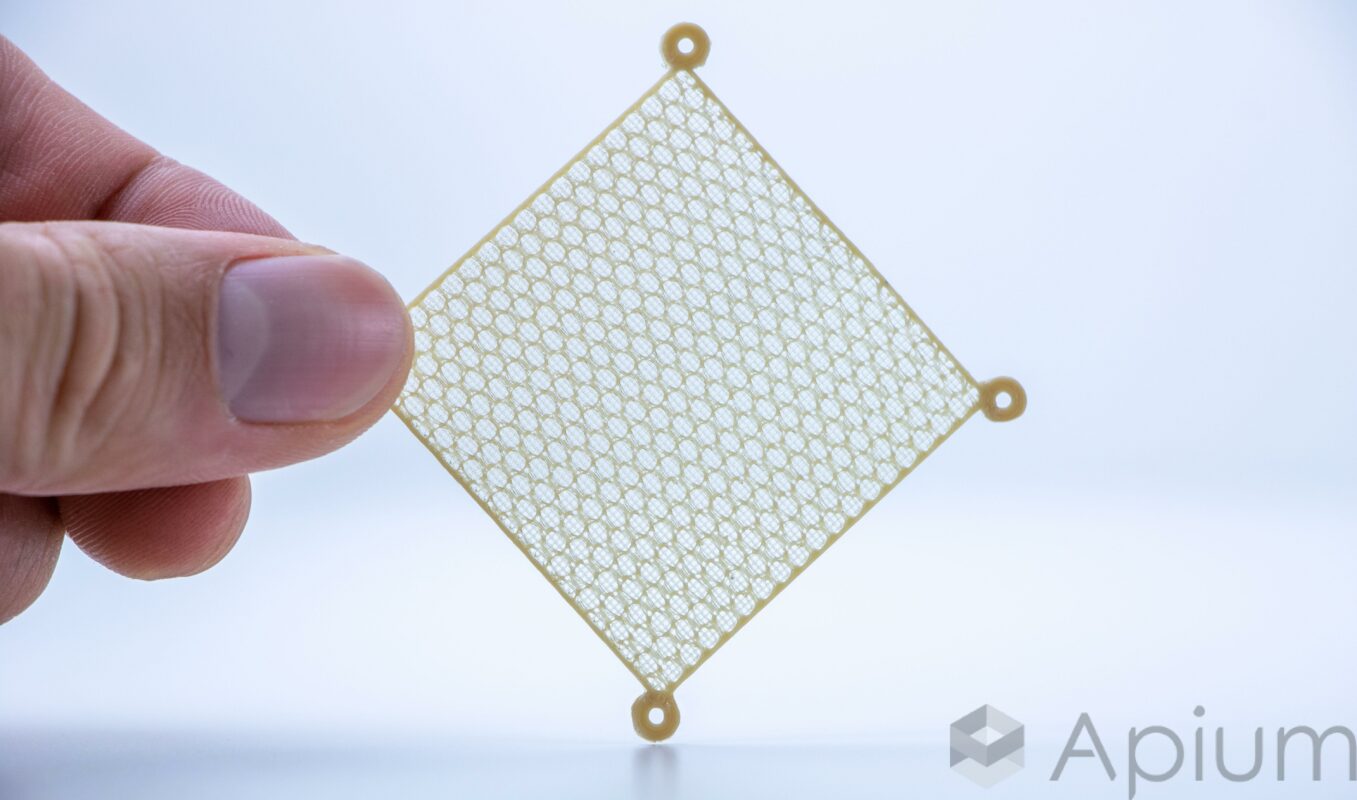

Biocompatible filaments

In cooperation with Evonik, materials and filaments were tested for their

biocompatibility and the corresponding tests were successfully

completed. This allows medical devices up to Class III to be manufactured

from PEEK.

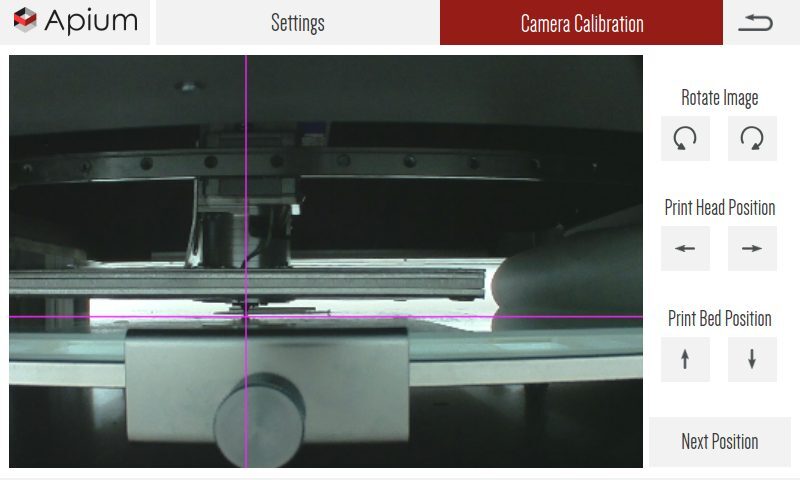

Monitored printing process

By integrating a camera system, temperature recording and

servomotors, the printing process is continuously monitored. This enables

the printer to intervene automatically when deviations occur.

Reproducibility

Integrated calibration routines guarantee consistent component quality. The software automatically informs about incoming maintenance operations and guides step-bystep through the procedures.

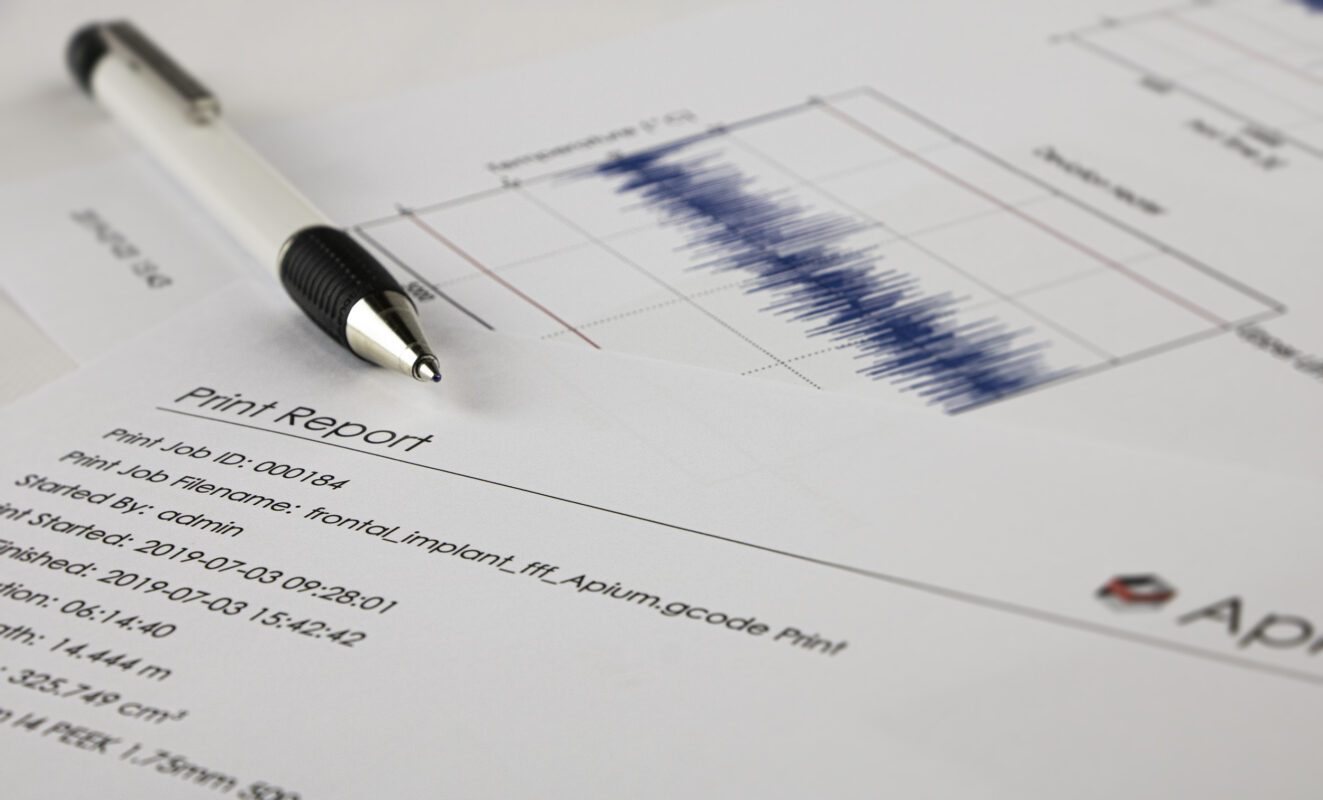

Documentation & Safty

All important parameters concerning the printing process are automatically

provided in a PDF protocol. The integrated user administration prevents unwanted access. For your data security, we have decided against cloud based solutions.

Integrated software

The control software is specially adapted to our printer hardware and

optimized for processing high-performance polymers. An intuitive user interface allows an easy handling of the printer. You can manage print jobs and check the status of the printer at any time.

Technical support

Our service department will train you in the handling of your printer. We

will be happy to answer any questions you may have about the printer and

other challenges of 3D printing.

Technical Data

Build Size |

130 x 130 x 120 mm |

Printer Size |

850 x 685 x 675 mm |

Nozzle Diameter |

0.2 – 0.8 mm |

Layer Thicknesses |

0.05 – 0.6 mm |

Wall Thickness |

> 250 µm |

Printhead-Temperature |

Up to 540ºC |

Hot Air Filter System |

Up to 280ºC |

Print Bed Material |

Stainless steel 316L |

Noise Emission |

< 70 dB(A) |

Data Formats |

STL, OBJ, G-Code |