Formlabs

Septillion Co., Ltd.2025-03-05T14:43:04+07:00This post is also available in: ไทย (Thai) 日本語 (Japanese)

Your Trusted Partner for High-Performance Printing

From prototypes to end-use parts, the Formlabs Form 4 delivers precision and reliability every time. Trusted by engineers and designers worldwide, it’s the go-to solution for demanding applications.

Experience Unmatched Excellence with EOS 3D Printing

For over three decades, EOS has been at the forefront of industrial 3D printing, delivering cutting-edge solutions to businesses worldwide. Known for its precision-engineered polymer and metal additive manufacturing technologies, EOS supports industries ranging from aerospace and automotive to healthcare and consumer goods. With a focus on innovation, sustainability, and quality, EOS continues to redefine manufacturing processes with its state-of-the-art 3D printers and premium materials.

In 2011, three MIT graduate students built the first 3D printer that could achieve industrial, professional part quality at an affordable price.

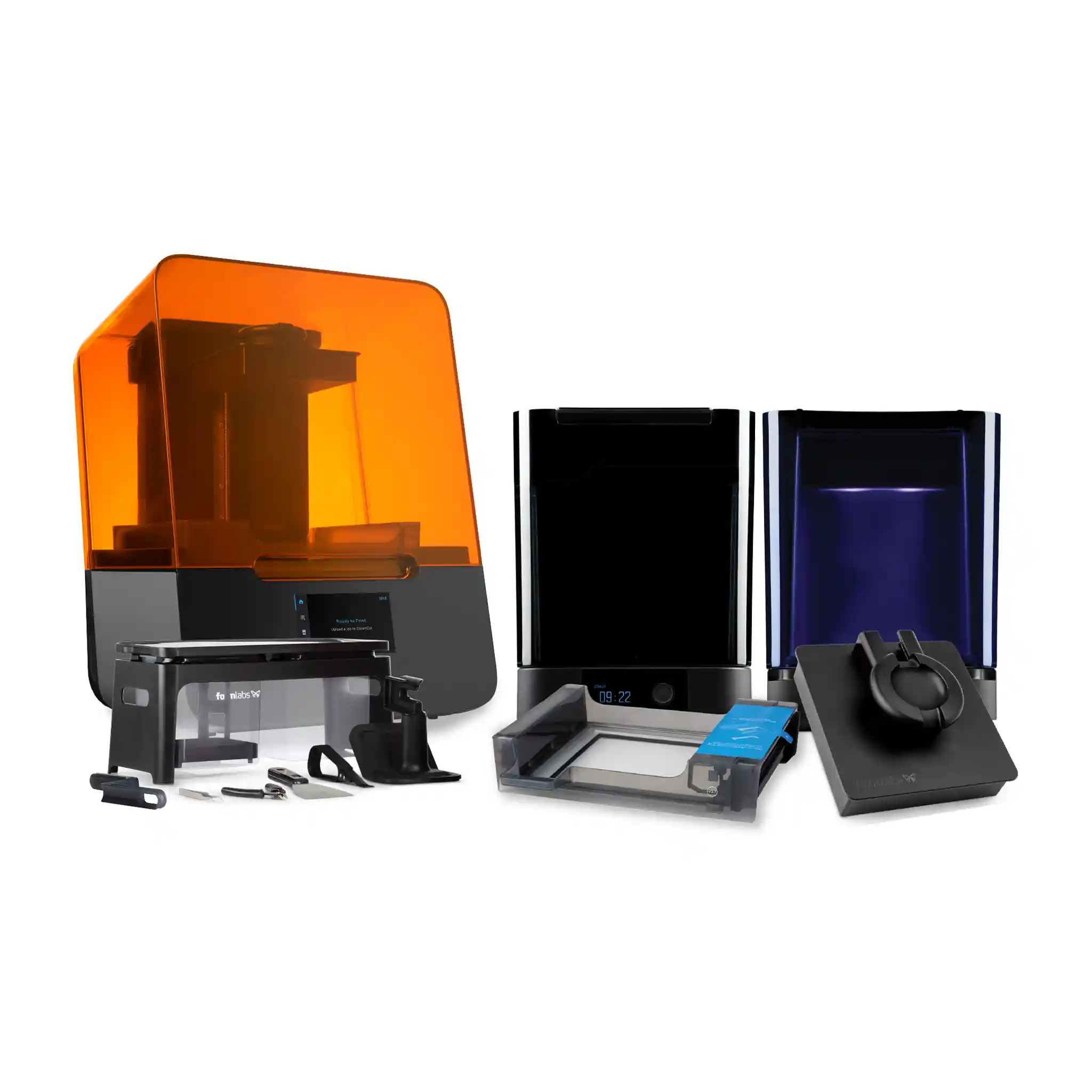

Formlabs Form 4 Series: Precision-Driven SLA 3D Printing

The Formlabs Form 4 Series represents the pinnacle of SLA technology, offering unmatched accuracy, speed, and ease of use.

Formlabs Form 4L Series: Large-Scale SLA Excellence

Formlabs Form 4L Series: Large-Scale SLA Excellence

Unlock new possibilities

Formlabs SLA 3D Printer

Your Trusted Partner for High-Performance Printing

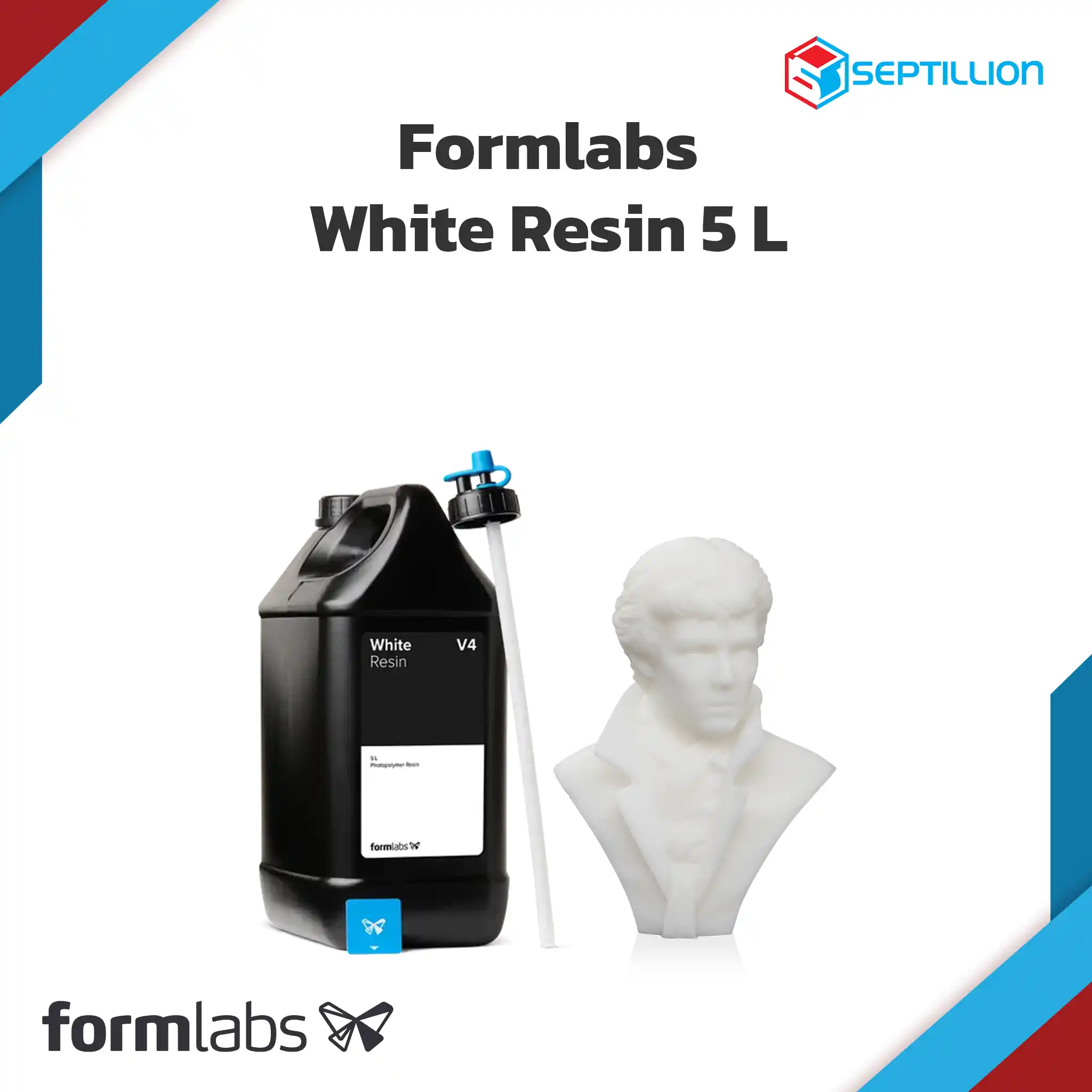

Formlabs General Purpose Resins: Versatility at Its Best

Formlabs Engineering Resins: Built for Strength and Precision

Formlabs Jewelry Resins: Crafting Perfection for Jewelers

Formlabs Dental Solutions: Precision for Modern Dentistry

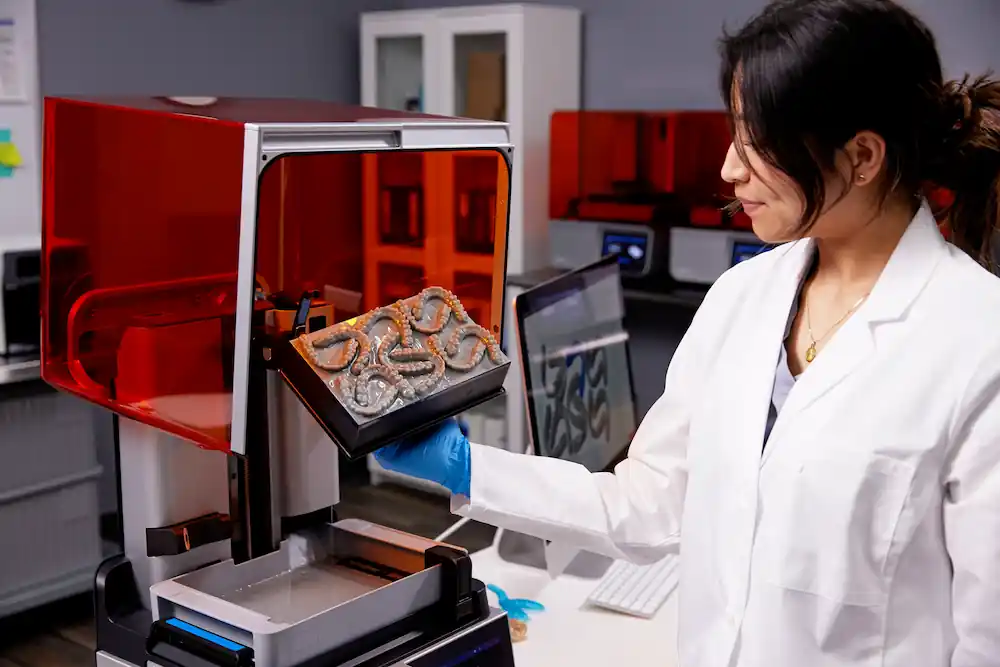

Formlabs redefines dental workflows with its comprehensive Dental Solutions, trusted by professionals worldwide.

The Formlabs ecosystem integrates state-of-the-art printers, biocompatible resins, and digital workflows to ensure accuracy and efficiency. Whether you’re crafting surgical guides, dentures, or orthodontic models, Formlabs delivers reliable results tailored to the dental industry.

Formlabs Dental Resins: Biocompatibility and Accuracy

Formlabs Medical Resins: Innovations in Healthcare

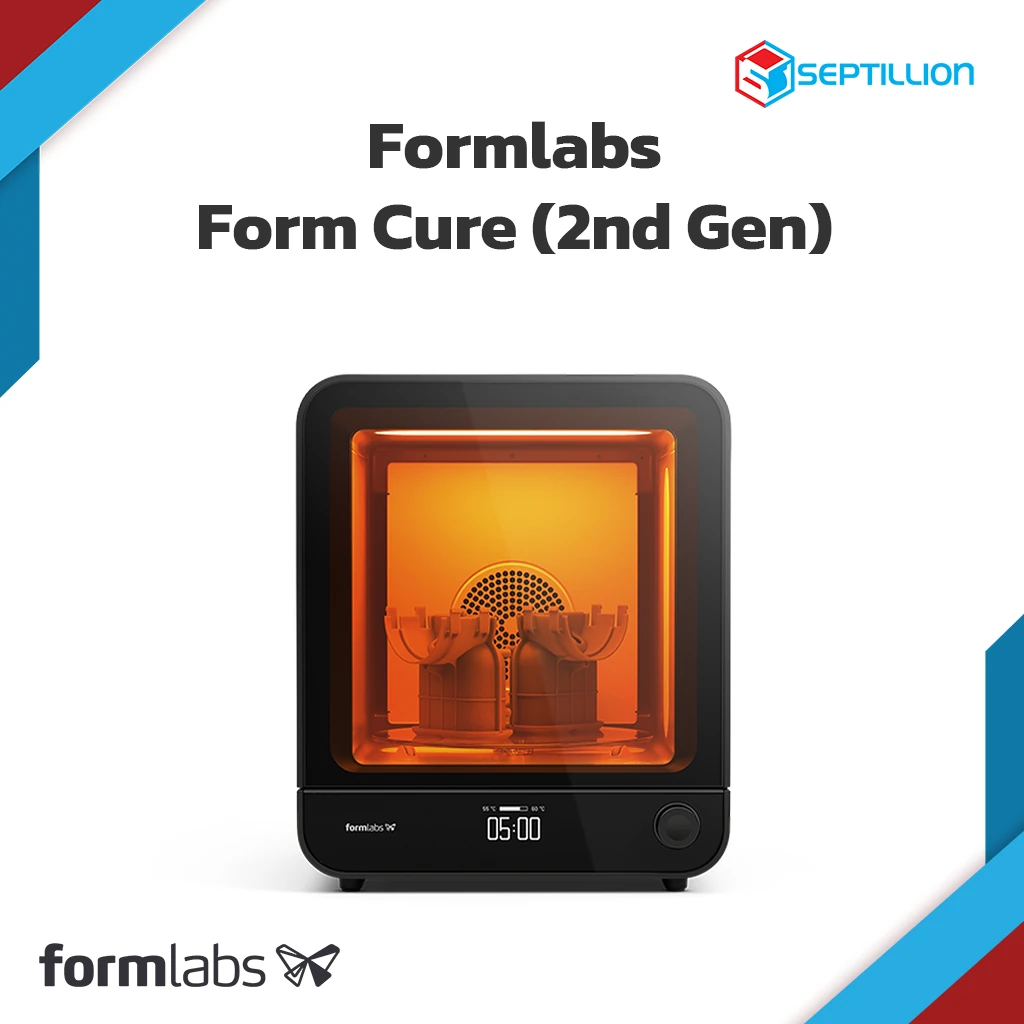

Formlabs SLA Post-Processing: Ensuring the Perfect Finish

Achieve professional-grade results with Formlabs SLA Post-Processing solutions.

Formlabs Form Cure (2nd Generation)

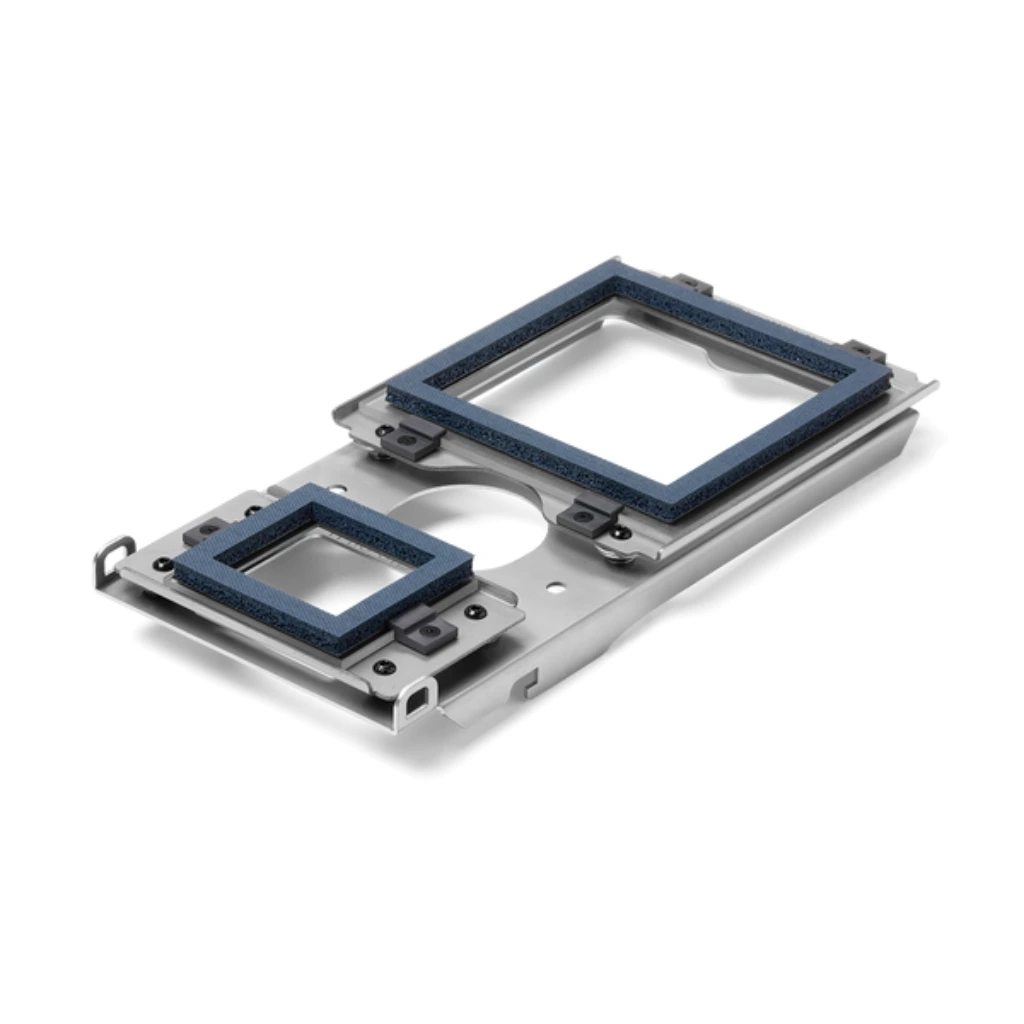

Formlabs SLA Spare Parts: Supporting Your Printer's Longevity

Keep your SLA printer running at peak performance with Formlabs SLA Spare Parts. Whether you need replacement resin tanks, build platforms, or optical components, Formlabs offers a wide range of genuine spare parts to ensure reliability and precision in every print.

Formlabs SLS Solutions: Precision in Powder-Based Printing

The Formlabs SLS Solutions are ideal for creating durable, end-use parts and functional prototypes.

Formlabs SLS Post-Processing: Enhance Durability and Aesthetics

Streamline your post-print workflow with Formlabs SLS Post-Processing tools. From cleaning with the Fuse Sift to achieving a smooth finish with media blasting, Formlabs provides solutions to prepare your parts for end-use or further processing. Efficient and user-friendly, these tools help you get the best out of your SLS prints.

Formlabs SLS Materials: Reliable and Cost-Efficient

Formlabs SLS Materials, such as Nylon 12 Powder and Nylon 12 GF, combine strength, flexibility, and durability. These materials are designed for functional prototypes and production parts, offering excellent mechanical properties and high resistance to wear and tear. With an easy-to-use workflow, Formlabs SLS materials ensure cost-effective manufacturing without compromising quality.

Formlabs SLS Spare Parts: Keep Your Workflow Seamless

Ensure uninterrupted operations with Formlabs SLS Spare Parts. From replacement build chambers to filters and powder cartridges, Formlabs offers authentic spare parts designed to maintain the performance and longevity of your Fuse Series printers.

Why Choose Formlabs?

Keep Your Workflow Seamless

Ensure uninterrupted operations with Formlabs SLS Spare Parts. From replacement build chambers to filters and powder cartridges, Formlabs offers authentic spare parts designed to maintain the performance and longevity of your Fuse Series printers.