3D Systems SLA 750

- Home

- Shop

- 3D printer, 3D Systems 3D Printer

- 3D Systems SLA 750

3D Systems SLA 750

The SLA 750 delivers high-speed and precision for rapid prototyping.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

S3D Systems SLA 750 – High-Speed Stereolithography

Revolutionize your prototyping with fast and accurate printing

3D Systems SLA 750 is a high-speed stereolithography (SLA) printer that revolutionizes prototyping with its fast and accurate printing capabilities.

Designed for professionals, it produces high-quality, detailed parts suitable for a range of applications, from engineering to healthcare.

Production-Grade SLA Workflow Solution

The SLA 750 solution delivers a breakthrough in additive manufacturing productivity, speed, reliability, and automation from the leading innovator in stereolithography (SLA) 3D printing. A full solution is comprised of the SLA 750 family of large-format 3D printing systems, advanced production-grade photopolymer materials, the PostCure 1050 post-processing system, and the Oqton cloud-based, end-to-end manufacturing operation system.

Large Production Parts at High Speeds

From the original inventor of SLA and the innovation leader in production-grade photopolymer technology, 3D Systems introduces the industry’s fastest SLA 3D printers: The SLA 750 and the SLA 750 Dual.

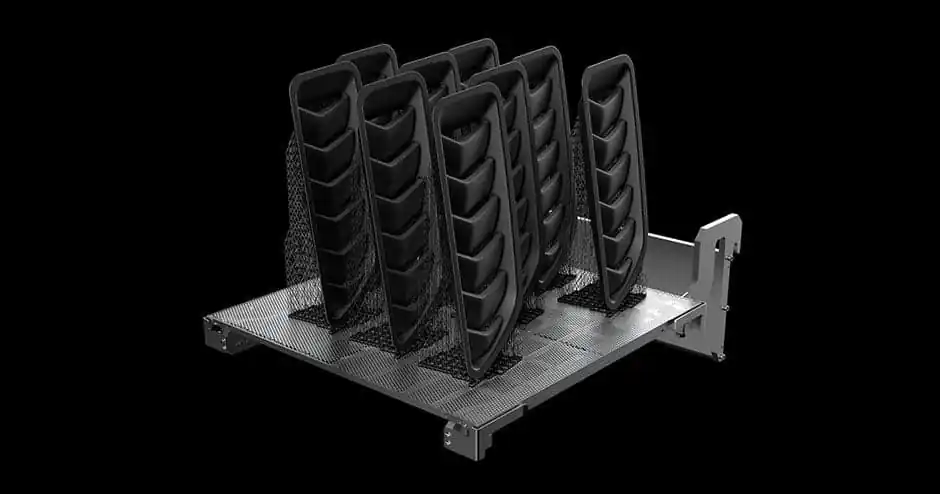

The SLA 750 Dual is the world’s first synchronous dual-laser SLA printer delivering up to twice the speed and triple the throughput of current SLA printers, using dual imaging systems together with a proprietary scan algorithm, Hyper-Scan™ vector technology, developed especially for efficient, high-quality production manufacturing.

The single-laser SLA 750 is field upgradeable to the dual-laser SLA 750 Dual, allowing you to rapidly scale productivity with increased demand.

Industrial-Scale Post-Processing with PostCure™ 1050

PostCure 1050 is an industrial-scale post-processing system with up to 10 times higher throughput compared to current similar systems, including high volume, high-speed drying and curing for batch jobs and large parts up to 1050 x 750 x 600mm. Featuring optimized light wavelengths, a separately configurable UV intensity, and actively cooled LEDs with separately adjustable heating, you can now ensure optimal part curing without incurring unwanted thermally induced warp in your printed parts.

Fleet Automation Readiness with 24/7 Lights-Out Operation

The SLA 750 and SLA 750 Dual come with downstream automation readiness and robot-compatibility for 24/7 lights-out operation including fully automatic printer turnover with job off-loading, washing, and on-boarding. Both 3D printers come with a robot accessible chamber handle, fixed START and STOP buttons, robot cycle start controls similar to existing CNC machines, automatic bottle or bulk material feed and connectivity ports.

Tech Specs

- Stereolithography (SLA) technology

- Max part size: 29.5 x 29.5 x 21.65 in (750 x 750 x 550 mm)

- High power 4-watt laser

- Dynamic beam range (0.125 to 1 mm)

- Choice of single or dual laser scanning (upgradeable)

- Max resolution: 2000 dpi

- Self-calibrating dual rail recoater

- Remote monitoring and control