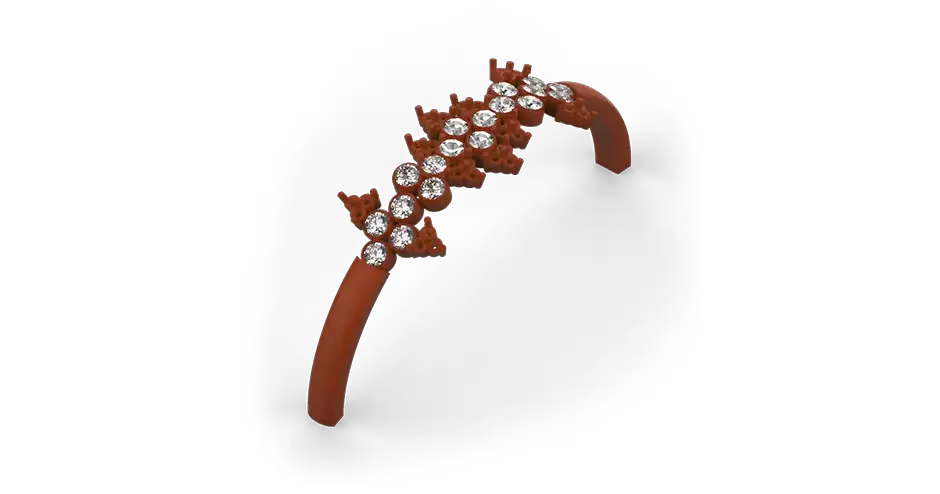

VisiJet Wax Jewel Ruby

- Home

- Shop

- Wax Material

- VisiJet Wax Jewel Ruby

VisiJet Wax Jewel Ruby

VisiJet Wax Jewel Ruby offers several advantages for jewelry casting, including high precision and fine detail reproduction, which ensures intricate designs are captured with accuracy. Its smooth surface finish minimizes the need for additional post-processing, saving time and effort. The resin is durable, providing stable and reliable casting patterns that maintain their shape during the casting process. Additionally, VisiJet Wax Jewel Ruby is designed to burn cleanly, reducing the risk of residue and ensuring a flawless final product. These features make it an ideal choice for jewelers seeking efficiency and high-quality results in their casting applications.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

VisiJet Wax Jewel Ruby is a high-precision wax resin

Offering detailed accuracy and a smooth finish

VisiJet Wax Jewel Ruby is a high-precision wax resin designed specifically for jewelry casting. It offers exceptional detail and smooth surface finishes, making it ideal for creating intricate and accurate jewelry patterns. This resin ensures durability and high-quality results, providing a reliable solution for producing detailed casting molds. With its superior resolution and excellent dimensional accuracy.

Document TDS.PDF

Wax / Jewelry

Bring intricate designs to life with durable, flexible, and dimensionally stable 3D printed pure wax casting patterns.

Discover next-level jewelry production with 3D printed wax jewelry patterns

Durable yet flexible casting patterns enable the production of new design styles, opening up new possibilities in wax 3D printing. Patterns produced using VisiJet® Wax Jewel Ruby material withstand handling through the entire lost wax casting process, and remain stable even in high ambient temperatures. Pattern durability and increased flexibility promote productivity and cost savings by reducing the time and costs associated with fragile patterns breaking. This pure wax is the best performing material for stone-setting.

Applications

- Typical and custom jewelry designs

- Stone in-place castings

- Fine mesh and filigree design jewelry castings

Benefits

- Durability and dimensional stability in high temperature environment

- For use with standard lost wax casting processes

- Clean burnout with no ash content

- Allows for fine featured designs with filigree or mesh patterns

Features

- 100% Wax

- Increased flexibility over traditional casting waxes

- Increased pattern durability

- High contrast dark red color for details visualization