3D Systems EXT 800 Titan Pellet

- Home

- Shop

- 3D printer, 3D Systems 3D Printer

- 3D Systems EXT 800 Titan Pellet

3D Systems EXT 800 Titan Pellet

The EXT 800 Titan Pellet makes 3D Systems’ high-speed pellet extrusion additive manufacturing technology accessible to organizations without the need or budget for one of our larger systems.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

EXT 800 Titan Pellet

Accessible high-speed industrial pellet extrusion 3D printer

The EXT 800 Titan Pellet harnesses the speed, reliability, and efficiency of 3D Systems’ pellet extrusion printing for organizations that do not need the build capacity of our larger EXT Titan Pellet systems. ready to meet the challenges of demanding industrial production with applications from foundry patterns and manufacturing fixtures to prosthetics and durable goods.

Space-Saving Design

The EXT 800 will fit through standard double doors, enabling office or lab installation while still boasting a sizeable build volume of 800mm x 600mm x 800mm (31.5” x 21.6” x 31.5”).

Faster than Filament

Save time with our proven high-throughput pellet extrusion system, enabling up to 10X the output of competing FFF and FDM printers.

Affordable Additive

Thermoplastic pellet feedstocks reduce material costs up to 10X compared to filaments. The EXT 800 is also our most affordable pellet extrusion system, accelerating your path to positive ROI.

Reliable and Repeatable

Industrial Production

The EXT 800 Titan Pellet harnesses the speed, reliability, and efficiency of 3D Systems’ pellet extrusion printing for organizations that do not need the build capacity of our larger EXT Titan Pellet systems. The EXT 800 is ready to meet the challenges of demanding industrial production with applications from foundry patterns and manufacturing fixtures to prosthetics and durable goods.

With a welded steel frame, industrial CNC controller, servo-driven ball screws on all axes, and an actively heated, enclosed build chamber, the EXT 800 is built for reliable, lights-out additive manufacturing. The large touchscreen HMI allows easy access to printer functions while safety features like door interlocks and material feed run-out detection ensure safe operation.

Access the Efficiency of Pellet Extrusion

Like our larger EXT Titan Pellet systems, the EXT 800 features our proven high-throughput pellet extruder enabling high print speeds with a wide range of low-cost thermoplastic pellets including ABS, ASA, PETG, and PLA. With a heated bed capable up to 140°C and an actively heated chamber up to 80°C, the EXT 800 can print a range of engineering materials including carbon fiber-filled PA, PC, PEI, and PEKK. Pellet extrusion also enables printing of highly flexible and elastic materials including TPEs as soft as shore 26A.

Designed for High-Throughput AM Production

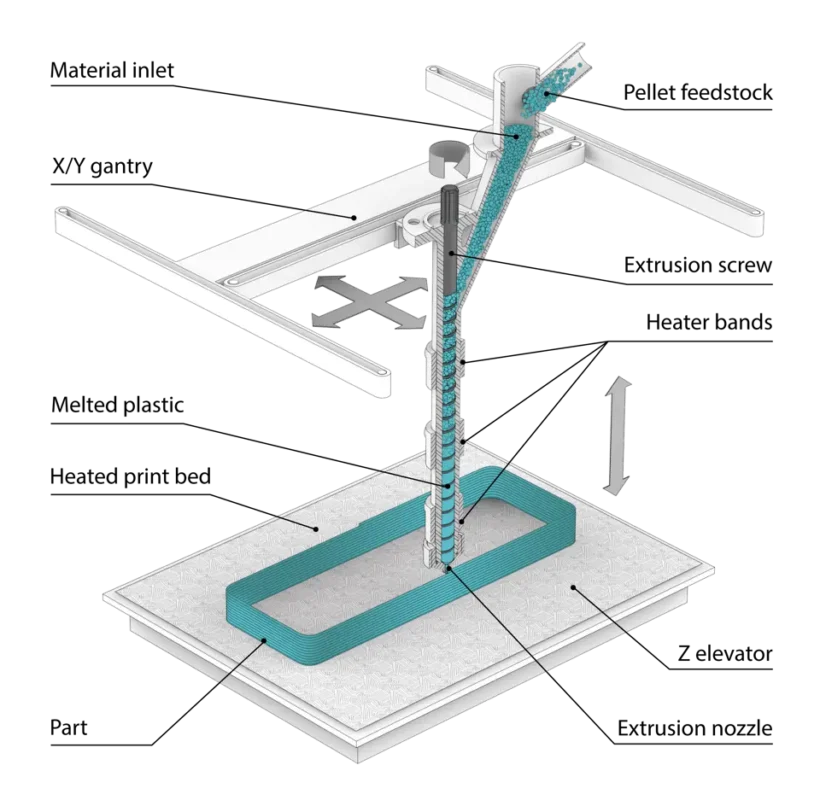

3D Systems’ pellet extrusion technology, sometimes referred to as Fused Granulate Fabrication (FGF), is similar to Fused Filament Fabrication (FFF/FDM) processes in that the extrusion toolhead melts thermoplastic feedstock and deposits the melted material layer by layer to build an object. However, 3D Systems’ pellet extrusion enables much higher throughput while saving significant cost compared to filament-based printers.

Build Volume

- Print: 800mm X 600mm X 800mm (31.5” x 23.6” x 31.5”)

Toolhead Configuration

- Single High-Throughput Pellet Extruder

Temperatures

- Pellet Extruder: 400°C

- Bed: 140°C

- Enclosure: 80°C

Extrusion Capabilities

- Pellet Nozzle Diameters: 0.6 mm – 9.0 mm

- Pellet Layer Heights: 0.4 mm – 6.0 mm

- Pellet Extruder Throughput: 0.45kg – 13.6kg* (1lb – 30lbs*) per hour

Control System

- Motion Controller: CNC Controller

- Drives: Servos on all axes

- Print Speeds: Up to 0.5m/sec

- Slicing Software: Simplify3D

Optional Accessories

- Material Dryer: Integrated Pellet Dryer