Septillion: Visit Kings 3D Printing – One of The Biggest 3D Printing in China

- Home

- Articles

- 3D Printing News, Article

- Septillion: Visit Kings 3D Printing – One of The Biggest 3D Printing in China

Septillion: Visit Kings 3D Printing – One of The Biggest 3D Printing in China

This post is also available in: ไทย (Thai)

Kings 3D Printing was established in 2008 under the name Shantou, Kings later expanded into a leading force in the 3D printing industry.

Kings 3D Printing was founded in 2008 under the name Shantou, Kings 3D Printing has grown into a leading force in the 3D printing industry. The company’s expansion to Shenzhen in 2015 marked a major turning point, as it established a standardized 3D printer production base and focused heavily on continuous research and development of printing materials. Over the years, Kings 3D has expanded its product lineup to include a wide range of advanced printers and materials, catering to key industries such as aerospace, automotive, and healthcare.

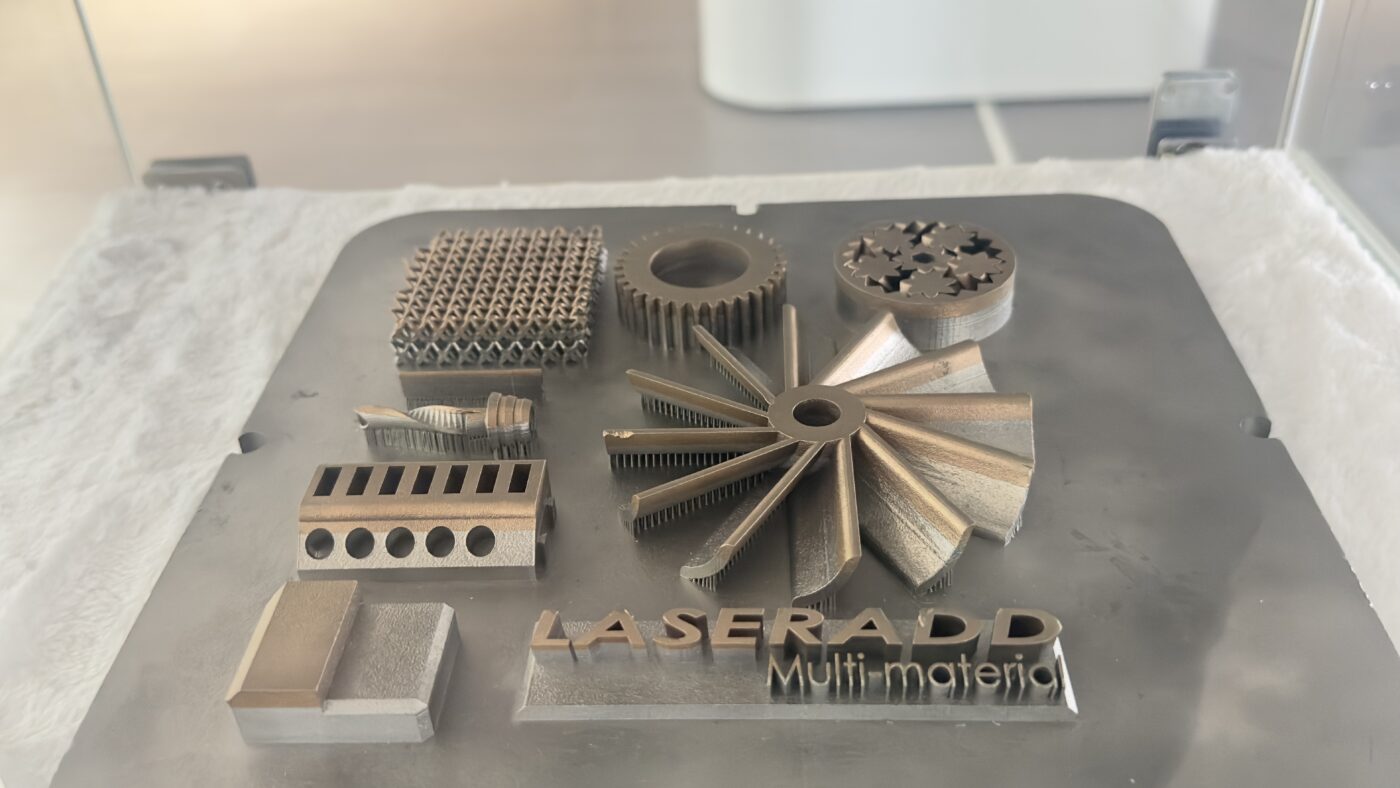

Kings 3D Printing has six types of 3D printers: SLA, SLM, SLS, FGF, DLP, and FDM—supporting applications ranging from prototyping to full-scale industrial production. The company also develops its own printing materials, such as UV resin, metal powder, and nylon pellets, ensuring optimal quality and performance.

With a strong commitment to technological advancement, Kings 3D has continued to expand its capabilities, including the acquisition of Laseradd in 2022 to strengthen its leadership in both metal and non-metal 3D printing technologies. Today, Kings 3D operates global manufacturing facilities in Zhuhai, Guanjin, and Jiaxing to meet the growing demands of the market.

Fueled by a vision of innovation, Kings 3D is committed to creating solutions that empower industries and designers around the world to bring their ideas to life with precision and reliability. Discover new possibilities with Kings 3D and become part of the future of manufacturing and design.

Kings 3D is also a leading expert in industrial laser 3D printers, utilizing SLA UV-curing technology for fast and highly accurate prototyping. Our printers work by curing liquid resin layer by layer with a light source, delivering high-quality results trusted by thousands of clients worldwide in industries such as automotive, aerospace, and healthcare.

Dedicated to delivering excellence, Kings 3D provides professional training, machine installation, customization, and ongoing maintenance, backed by a responsive after-sales support team. Our goal is to ensure optimal product performance and support the long-term success of our clients with full lifecycle care.

Kings 3D has established a robust manufacturing network across China, with strategic production bases in key regions including Guangdong, Jiangxi, Zhejiang, Shanghai, Jiangsu, Tianjin, Shaanxi, Sichuan, Chongqing, and Hunan. This geographic spread enables us to meet both domestic and international demand efficiently, offering rapid delivery and consistently high-quality products.

The factories are located in Zhuhai (Guangdong), Pingxiang (Jiangxi), and Pinghu (Zhejiang)—each equipped with state-of-the-art manufacturing and R&D facilities. These centers support large-scale production and continuous innovation in 3D printing technology and materials.

Today, Kings 3D printers are sold in over 40 countries across six continents, reflecting global trust in our technology and product quality. With strategic expansion in China’s major industrial hubs, Kings 3D remains a leader in the 3D printing revolution—delivering cutting-edge solutions to industries such as automotive, aerospace, medical, and more. Backed by powerful production capabilities, Kings 3D is committed to driving innovation and maintaining leadership in the 3D printing industry, providing world-class products and advanced technologies to customers worldwide.

Topic:

What does Kings 3D Printing do?

3d Printing for Automotive Parts

Drive into the Future with Kings 3D’s Cutting-Edge Automotive 3D Printing Technology

Experience unmatched precision, custom designs, and sustainable solutions that fuel innovation in the automotive industry.

Biggest Printing:

Equipped with the largest 3D printer in the country with a build size of 1.7 meters, Kings 3D supports integrated printing solutions tailored for automotive modification needs.

Precision Meets Complexity:

With an impressive printing accuracy of 0.05 mm, our technology delivers ultra-fine details—comparable to a strand of hair—while effortlessly handling complex geometries in both design and production. It supports high levels of customization for intricate shapes.

Wide Range of Materials:

Support a variety of materials, including resin, metal, and nylon, catering to a diverse range of specialized industry requirements.

Rapid Prototyping:

From creative design to finished prototype, the entire process can be completed in as little as 12 hours—ensuring fast turnaround and increased production efficiency.

Low Investment, Quick Return:

Kings 3D Printing’s solutions help significantly reduce development timelines, R&D costs, and production expenses—delivering a fast return on investment.

เครื่องใช้ภายในบ้าน

Home appliances are essential to everyday life, including air conditioners, refrigerators, washing machines, audio systems, vacuum cleaners, electric fans, kettles, coffee makers, rice cookers, juicers, mobile phones, and many other small electronic devices. With such a wide range of appliance types, it’s clear that 3D printing has great potential for application. But why use 3D printers to create appliances? Why are manufacturers shifting from traditional methods to 3D printing?

In today’s highly competitive market, more and more appliance manufacturers are adopting 3D printing technology for product prototyping, significantly enhancing the efficiency of their design process.

The Application of 3D Printing Across Industries

The Importance of Prototypes in Product Design

Prototypes play a crucial role in product design as they form the basis for communication and refinement of the concept. Compared to 2D models or virtual 3D simulations on a computer, physical prototypes created through 3D printing provide a more tangible and detailed representation of the design. Moreover, 3D printers greatly reduce the time required to produce molds, resulting in significant cost savings—especially in resin-based manufacturing.

Eliminating Design Constraints

3D printing technology allows for the direct and rapid creation of prototypes without limitations on the structure or form of a product. This greatly shortens the design cycle. Kings3D’s SLA printers are fully capable of handling such tasks, including the prototyping of air conditioners, mobile phones, washing machines, electric irons, and other appliances.

The Importance of Prototypes in Product Design

Prototypes play a crucial role in product design as they form the basis for communication and refinement of the concept. Compared to 2D models or virtual 3D simulations on a computer, physical prototypes created through 3D printing provide a more tangible and detailed representation of the design. Moreover, 3D printers greatly reduce the time required to produce molds, resulting in significant cost savings—especially in resin-based manufacturing.

Eliminating Design Constraints

3D printing technology allows for the direct and rapid creation of prototypes without limitations on the structure or form of a product. This greatly shortens the design cycle. Kings3D’s SLA printers are fully capable of handling such tasks, including the prototyping of air conditioners, mobile phones, washing machines, electric irons, and other appliances.

The Application of 3D Printing Across Industries

(1) Design Discussion and Presentation:

In the early stages of product development, this technology facilitates effective design communication between departments. It not only saves time but also helps reduce design errors.

Entertainment Industry

3D printing technology and cartoon art are closely interconnected, as 3D modeling is often followed immediately by 3D printing. More and more designers are bringing their cartoon creations into the real world, and today, 3D printing technology is widely used in cartoon design and production across three main areas:

1. Stop-Motion Animation

One of the most common applications of 3D printing technology in the cartoon industry is in stop-motion animation. Compared to traditional production methods, 3D printing allows for a wider variety of materials beyond just clay or fabric. It significantly enhances both efficiency and production quality, as 3D printed sets and characters offer higher precision and detail, along with more realistic expressions and movements.

2. Character and Scene Design

Character design is one of the most crucial and time-consuming parts of cartoon creation. Utilizing 3D printing to produce prototypes of main characters can effectively reduce the initial design workload and streamline the creative process.

3. Merchandising and Spin-off Products

As consumer tastes become increasingly diverse and personalized, cartoon-related merchandise is trending toward more customized designs. People are more inclined to create these items themselves. 3D printing technology enables fans to produce customized merchandise based on their favorite cartoons, making it feel like they’re receiving bespoke, made-to-order products.

Handicrafts, Gifts, and Jewelry

Application of 3D printing technology in handicrafts and jewelry:

In the custom-made crafts market, decorative accessories, wood carvings, and other handmade gift items are often visually stunning but difficult to replicate. Intricate hollow patterns or internal carvings are especially complex and challenging to craft by hand — challenges that can be overcome through the use of 3D printing technology.

Applications of 3D Printing in Handicrafts and Jewelry

- High-precision artistic sculptures and handmade gifts

- Rapid production of customized gift items

- 3D digital modeling for large-scale engraving projects

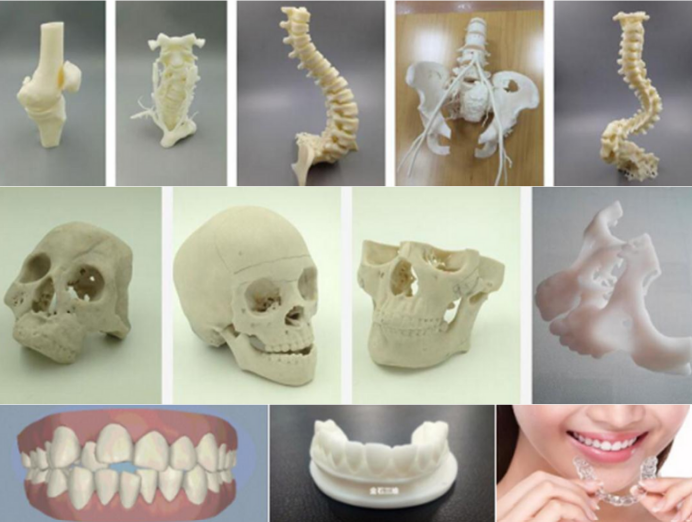

Medical Applications of 3D Printing Technology

With strong support from government policies, technological innovation, and the growth of digital healthcare, the demand for medical products in China has increased rapidly. As a result, 3D printing technology is being increasingly adopted in the medical field, particularly for small, highly precise medical aids and accessories.

Due to favorable policies, the development of healthcare information systems, and ongoing technological revolutions, the demand for medical devices in China continues to grow. 3D printing is playing a growing role in this sector — especially in producing small-scale medical aids and precision accessories such as diagnostic tools.

Medical Applications of 3D Printing Technology

Enhancing the safety and efficiency of surgical procedures, reducing the risk of medical errors

Driving innovation in the design of medical devices

- 3D printing enables the creation of complex devices that traditional manufacturing methods cannot produce, addressing specific medical treatment needs.

Production of Medical Accessories

- The development of customized medical equipment for research and clinical applications helps lower costs, increase efficiency, and maintain quality standards.

Clinical Support Tools and Presentations

- 3D-printed anatomical models accurately replicate human physiology, providing crucial references for doctors to improve diagnostic accuracy before treatment.

Clinical Equipment Testing

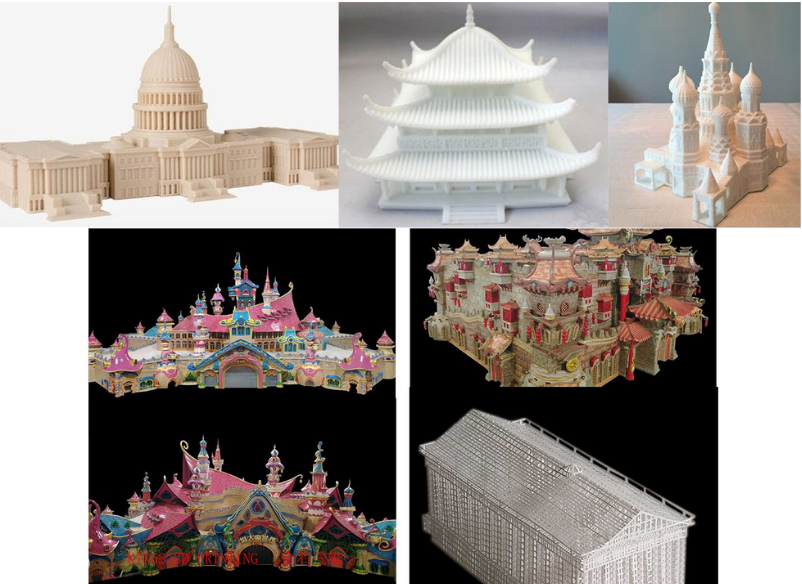

Architectural Models

Traditional architectural model design relies on hand-drawn sketches and manual model-making, which is time-consuming. The Kings SLA 3D printer significantly reduces production time using laser curing technology.

Instead of the conventional process of designing from drawings and building models by hand, the KINGS SLA 3D printer uses laser curing technology to directly translate design concepts into physical form. It accurately reproduces the details from CAD digital files, printing smooth-surfaced resin models. This dramatically shortens production time and accelerates project timelines.

Advantages of 3D Printing Technology in Real Estate Model Making

3D printing technology offers flexibility in modifying models. If clients request design changes, updates can be made easily through digital files.

It enhances the design process.

- 3D printing quickly transforms sketches into prototypes, facilitating design evaluation and approval.

Rapid prototype model creation

- Architectural models can be printed quickly to provide clients with a clear visualization of a project.

Reduced time for architectural model building

- 3D printers significantly shorten the time required to create life-sized building prototypes.

Easily Editable

3D printing technology provides flexibility in model modification. If clients require changes in details, they can be easily made through digital files.

Industrial Prototypes for Manufacturing Efficiency

A prototype is an initial sample or model of a product used for testing before mass production. Generally, prototypes are used to evaluate new designs and enhance accuracy for system analysts and users. Prototypes are widely used in the manufacturing industry, playing a vital role not only in verifying the appearance and structure of products but also in reducing costs by avoiding financial losses due to direct forming failures. Additionally, they save time as they can be used to promote the product before entering mass production.

Applications of 3D Printing Technology in Prototyping

3D printing can be used to create injection molds, drawing dies, and die-casting molds, or to repair and restore existing molds.

3D printing is gradually replacing traditional mold-making techniques.

3D printing is gradually replacing traditional mold-making techniques.

It is especially suitable for small-batch production, personalized customization, and products with complex structures.

3D printing enables the direct production of molds or mold components.

Footwear Industry

KINGS is the first 3D printer manufacturer to offer comprehensive 3D printing solutions for the footwear industry. The applications of KINGS SLA 3D printing technology include:

- Shoe Prototypes – Quickly verify the appearance and structure of design concepts

- Casting Shoe Molds – Replace traditional wooden molds with CNC machining processes

- Soft Shoe Prototypes – Used for wear-testing to evaluate functionality and comfort

- Shoe Mold Production – Suitable for small-scale shoe manufacturing

- Finished Shoe Soles – Support custom-made footwear development and personalized production

Kings 3D Printing Environment & Applications

Author

Additive Manufacturing Solution Provider Since Feb 2013 Authorized Reseller / Distributors eos, Ultimaker, Zortrax, FlashForge, TierTime, Markforged, Pollen, BlackBelt 3D, Shinning 3D, Thor 3D Scanner, Agisoft, Autodesk Netfabb, Materialise