Bambu Lab H2D Pro

- Home

- Shop

- 3D printer, Bambu Lab 3D Printer

- Bambu Lab H2D Pro

Bambu Lab H2D Pro

฿139,900.00 Inc. VAT

- Dual-nozzle system enables multi-material and multi-color printing with fewer purge cycles for faster, cleaner output.

- Professional high-temperature printing with active 65°C chamber heating and intelligent airflow control for stronger, warp-free parts.

- Enhanced cooling fan in the toolhead improves thermal stability and prevents filament clogging.

- Tungsten carbide nozzle (HRA 90) offers exceptional durability and 50% longer lifespan with abrasive or fiber-reinforced filaments.

- Heavy-duty air filtration system with G3 pre-filter, H12 HEPA, and activated carbon filter effectively removes particles and VOCs.

- Enterprise-grade connectivity with Ethernet and WPA2-Enterprise Wi-Fi, including physical kill switches for network security.

- Enterprise integration support for customized printer management and fleet control.

- Efficient support material printing ensures smooth surface finish and easy removal.

- CoreXY motion system delivers high speed and precision for professional printing results.

- Fully assembled and ready to use out of the box.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

Bambu Lab H2D Pro

Experience next-level precision and speed with the Bambu Lab H2D Pro —

engineered for professionals who demand perfection in every print.

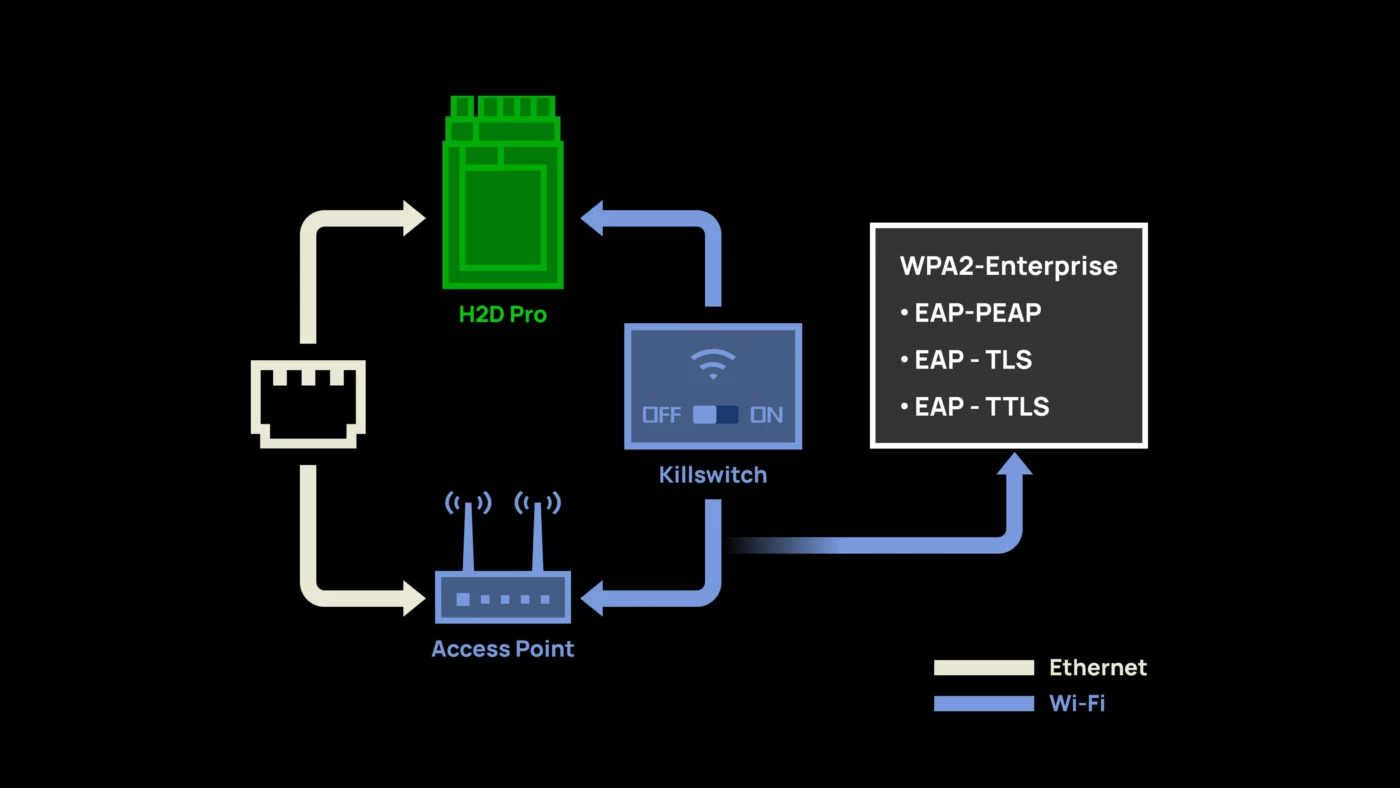

Professional Connection Options

Stable Ethernet Connection, WPA2-Enterprise Authentication Wi-Fi Connection

The H2D Pro offers the option to connect to your devices through its newly added Ethernet port, ensuring robust network communication in complex environments. Ethernet connectivity can also be used in crowded wireless signal environments. Additionally, the H2D Pro provides WPA2-Enterprise Wi-Fi Authentication (EAP-PEAP/EAP-TLS/EAP-TTLS) and individual physical kill switches for Wi-Fi, meeting stringent network security requirements.

Enterprise Integration Support

Tailor Solution For Printer Management

Bambu Lab provides professional support for enterprises to custom-develop efficient printer fleet management tools, meeting their business integration needs. Our expert software R&D team offers full technical assistance to help clients achieve their required customized functionalities. (For more details, please contact your local reseller)

Dual-NozzleEnhanced Productivity

Multi-Material PrintingFlexible and rigid, low cost and exotic materials in one print

Combine flexible and rigid materials in a single print to create impressive interlocking structures and innovative designs beyond traditional manufacturing. Pairing high-performance materials with standard ones further reduces costs and boosts material efficiency by using premium materials only where necessary.

Efficient Support Printing & Perfectly Smooth Interface

Print with support is no longer a headache. With H2D’s dual-nozzle setup, one nozzle can be reserved for dedicated support material, allowing secured print and perfect support interface.

Fast and efficient multi-color printing

Professional High-Temperature Printing Solution

Less failure, stronger prints

Improving high-temperature reliability

HRA 90 Tougher nozzle, lower maintainance

Heavy Duty Air Filtration

Effectively Filter Particulates And VOCs Generated by 3D Printing

What In The Box

Vision Encoder Plate

TECH SPECS OF THE BAMBU H2D PRO 3D PRINTER

| GENERAL | |

|---|---|

| Technology | Fused Deposition Modeling (FDM) |

| Motion System | CoreXY |

| Assembly | Fully-Assembled |

| Made in | China |

| MACHINE DIMENSIONS | |

| Outer Dimensions (w/o AMS)* (L × W × H) |

492×514×626mm (19.4″×20.2″×24.6″) |

| Net Weight (w/o AMS)** | 31kg (68.4lb) |

| PRINTING PARAMETERS | |

| Build Volume (L × W × H) |

SINGLE Extrusion 325mm × 320mm × 325mm (12.79″×12.59″×12.79″)DUAL Extrusion 300mm × 320 × 325mm (11.81″×12.59″×12.79″)Total Volume for Two Nozzles 350mm × 320mm × 325mm (13.77″×12.59″×12.79″) |

| Filament Diameter | 1.75mm |

| Extrusion | Dual Extrusion |

| Extruder Motor | Bambu Lab High-precision Permanent Magnet Synchronous Motor |

| Extruder Gear | Hardened Steel |

| Hotend | All-Metal |

| Nozzle Material | Tungsten Carbide Nozzle |

| Max. Nozzle Temperature | 350°C |

| Nozzle Size | 0.4mm |

| Max Build Plate Temperature | 120°C |

| Build Surface | Flexible Textured PEI Plate

OPTIONAL |

| Max Toolhead Speed | 1000mm/s |

| Max Toolhead Acceleration | 20,000mm/s² |

| Max Flow Rate (Standard Flow Hotend) |

40mm³/s* |

| Active Chamber Heating | Supported |

| Max Chamber Temperature | 65°C |

| Pre-Filter Grade | G3 |

| HEPA Filter Grade | H12 |

| AIR PURIFICATION | |

| Activated Carbon Filter Type | Granulated Coconut Shell |

| VOC Filtration | Superior |

| Particulate Matter Filtration | Supported |

| COOLING | |

| Part Cooling Fan | Closed Loop Control |

| Cooling Fan for Hotend | Closed Loop Control |

| Main Control Board Fan | Closed Loop Control |

| Chamber Exhaust Fan | Closed Loop Control |

| Chamber Heat Circulation Fan | Closed Loop Control |

| Auxiliary Part Cooling Fan | Closed Loop Control |

| PRINTER FEATURES | |

| Enclosed | Yes—Plastic & Glass |

| Frame | Aluminum and Steel |

| Filament Cutter | Built-In |

| Build Plate | Magnetic, Flexible |

| Bed Leveling | Fully-automated |

| Emergency Button | ✓ |

| Swappable Nozzle System | ✓ |

| Power Loss Recovery | ✓ |

| CAMERA(S) | |

| Live View Camera | Built-in; 1920 × 1080 |

| Nozzle Camera | Built-in; 1920 × 1080 |

| BirdsEye Camera | Built-in; 3264 × 2448 |

| Toolhead Camera | Built-in; 1920 × 1080 |

| SENSOR(S) | |

| Door Sensor | Supported |

| Filament Runout Sensor | Supported |

| Filament Tangle Sensor | Supported |

| Filament Odometry | Supported with AMS |

| COMPATIBLE MATERIALS | |

| Third-Party Filament | Yes*** |

| Supported | PLA, PETG, TPU, PVA, BV OH, ABS, ASA, PC, Nylon / PA, PET, PPS, PPA, and Carbon/Glass Fiber Reinforced Filament variants of the previously listed materials |

| COMMUNICATION | |

| Display | 5″ Capacitive Touch Screen |

| Display Resolution | 720 × 1280 |

| Storage | Built-in 8 GB EMMC and USB Port |

| Control Interface | Touchscreen, mobile App, PC App |

| Motion Controller | Dual-core Cortex-M4 and Single-core Cortex-M7 |

| Applicator Processor | Quad-core 1.5 GHz ARM A7 |

| Neural Processing Unit | 2 TOPS |

| NETWORK CONTROL | |

| Connectivity | Wi-Fi, Ethernet |

| Network Kill Switch | Wi-Fi & Ethernet |

| Wi-Fi Frequency Range | 2400 MHz – 2483.5 MHz |

| Wi-Fi WPA2-Enterprise | EAP-PEAP EAP-TLS TAP-TTLS |

| Wi-Fi Transmitter Power (EIRP) | ≤ 21.5 dBm (FCC) ≤ 20 dBm (CE/SRRC) |

| Wi-Fi Protocol | IEEE 802.11 b/g/n |

| Ethernet Socket | RJ45 |

| Ethernet Speed | 100 Mbps / Full Duplex |

| Removable Network Module | Yes |

| 802.1X Network Access Control | Yes |

| SOFTWARE | |

| Slicing Software | Bambu Studio

Supports third-party slicers which export standard |

| Compatible OS | Windows, MacOS |

| Supported File Format(s) | STL, 3MF |

| POWER REQUIREMENTS | |

| Input Voltage | 100 – 120 VAC / 200 – 240 VAC, 50/60 Hz |

| Max Power** | 1320 W@110 V 2200 W@220 V |

| Average Power | 1050 W@110 V 1050 W@220 V |