3D Systems DMP Factory 350 Dual

- Home

- Shop

- 3D printer, 3D Systems 3D Printer, Metal 3D Printer

- 3D Systems DMP Factory 350 Dual

3D Systems DMP Factory 350 Dual

DMP Factory 350 Dual offers dual-laser technology for faster, scalable metal 3D printing production.

Discover 3D Systems DMP Factory 350 Dual – dual-laser metal 3D printing for fast, scalable production.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

3D Systems DMP Factory 350 Dual – Industrial DMLS 3D Printer

Dual-laser, high-performance metal 3D printing for faster production

The 3D Systems DMP Factory 350 Dual uses dual-laser technology to double the production speed while maintaining precision.

Designed for industries needing fast, large-scale metal part production.

3D Systems DMP Factory 350 TDS

High Quality Powder and Process Management

The DMP Factory 350 has an integrated powder management system with high-performance sieving and significantly limited operator exposure to powder. The O2-free atmosphere of the powder workflow (consistently below 25ppm) guarantees highest part quality as well as maximum powder usage.

Designed for Scaling Production

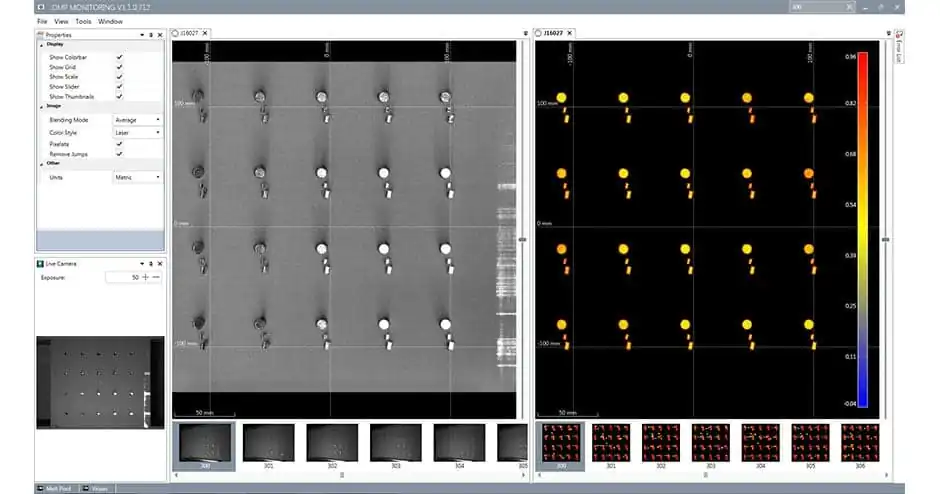

Automated workflow steps and a small footprint for reduction of overall required floor space help you efficiently scale your metal AM production. The real-time process monitoring with DMP Monitoring adds traceability and contributes to informed decisions on quality.

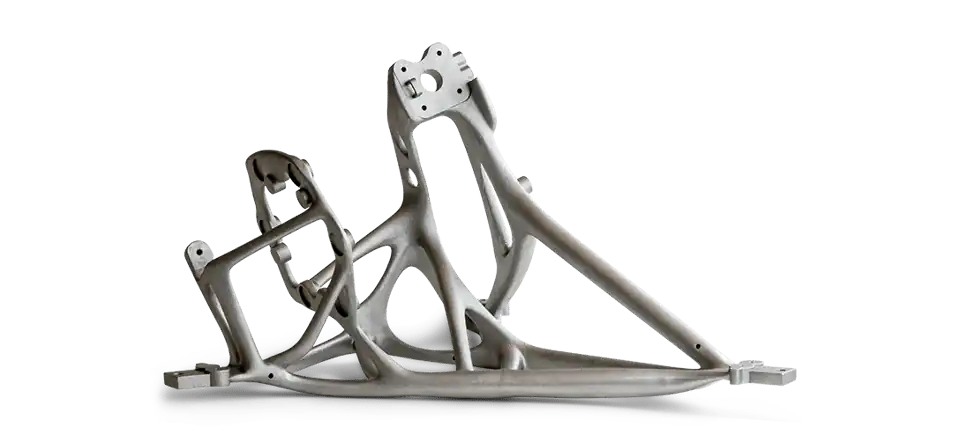

Unique Vacuum Chamber Concept for Highest Part Quality

Due to the unique vacuum chamber concept of the DMP Factory 350, argon gas consumption is heavily reduced while at the same time showing best-in-class oxygen purity (<25 ppm). This results in exceptionally dense parts with excellent mechanical properties.

Achieve High Quality Performance Even Faster

Now DMP Factory 350 comes in a two-laser configuration, reducing build times by up to 50 percent. The DMP Factory 350 Dual maintains the high quality and repeatability of the single-laser configuration while boosting productivity for lower operational costs.

| DMP Factory 350 Tech Specs | |

|---|---|

| Laser Power Type | 2 x 500W/Fiber laser1 |

| Laser Wavelength | 1070 nm |

| Single Build Volume (X x Y x Z) Height inclusive of build plate | 275 x 275 x 420 mm (10.82 x 10.82 x 16.54 ) |

| Layer Thickness | Adjustable, minimum 5 μm, typical values: 30, 60, 90 μm |

| Metal alloy options for dual laser configurations: | LaserForm Ti Gr1 (A)², LaserForm Ti Gr5 (A)², LaserForm Ti Gr23 (A)², LaserForm AlSi10Mg (A)3, LaserForm AlSi7Mg0.6 (A)3, LaserForm Ni625 (A)³, LaserForm Ni718 (A)³, LaserForm 316L (A)³, Certified Scalmalloy³, Certified M789 (A)³, Certified A6061-Ram2 (A)3, Certified CuCr2.4 (A)3, Certified Tungsten (A)², Certified CuCr1Zr (A)3, Certified HX (A)3, Certified CuNi30 (A)3, Certified C-103 (A)3, *GRX-810 |

| Material Deposition | Soft blade recoater |

| Repeatability | Δx (3σ) = 60um, Δy (3σ) = 60um, Δz (3σ) = 60um |

| Minimum Feature Size | 200 μm |

| Typical Accuracy | ± 0.1-0.2% with ± 100 μm minimum |

| Build Platform Heating | 250°C |