3D Systems EXT 1270 Titan Pellet

- Home

- Shop

- 3D printer, 3D Systems 3D Printer

- 3D Systems EXT 1270 Titan Pellet

3D Systems EXT 1270 Titan Pellet

The EXT1270 Titan Pellet is purpose-built for production additive manufacturing, capable of producing functional, high-performance parts in industries such as foundry, automotive, aerospace and defense, and consumer products.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

EXT 1270 Titan Pellet – 3D Systems Industrial FDM 3D Printer

Print large parts with excellent control using the EXT 1270 Titan Pellet

The EXT 1270 Titan Pellet offers high efficiency and accuracy for large-scale pellet printing.

Platform Common Specifications

Built for Production

The EXT 1270 Titan Pellet is purpose-built for production additive manufacturing, capable of producing functional, high-performance parts in industries such as foundry, automotive, aerospace and defense, and consumer products.

Featuring a welded steel frame and an industrial actively heated enclosure, the EXT 1270 is production-ready and can be upgraded with a second pellet extruder, filament printing capability, and/or CNC milling functionality either at the time of purchase or later on.

Whether you need patterns, molds, tooling, jigs, fixtures, end-use parts or full-scale prototypes, the EXT 1270 is a proven production solution.

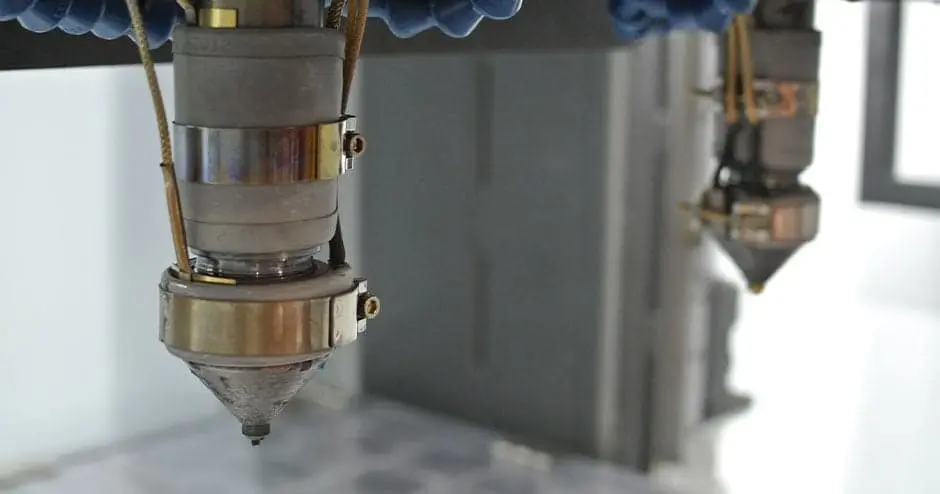

Pellet Extrusion on the EXT 1270

The EXT 1270 is proven with a wide variety of pellet materials, ranging from commodity feedstocks to high-temperature, high-performance materials such as CF-PEI, GF-PEKK, Nylons and Polycarbonate. Pellet extrusion also enables the use of highly flexible elastomers and high-percentage glass and carbon-filled materials that are difficult, or impossible, to print from filament all while reducing material costs up to 10X and delivering 10X higher deposition rates.

Hybrid Manufacturing on the EXT 1270

The EXT 1270 Titan Pellet features our proven pellet extrusion system and can be equipped with additional toolheads on the same gantry, such as a filament extruder or second pellet extruder, enabling high-speed, multi-material printing. With the optional CNC spindle toolhead, the EXT 1270 allows for true hybrid manufacturing, enabling the machining of 3D printed parts both during and after the printing process. Experience next-level production additive manufacturing with the EXT 1270, which shortens cycle times and produces smooth, accurate end-use 3D printed parts.

The machine features a build volume of 1270mm x 1270mm x 1829mm (50” x 50” x 72”), providing ample space for both printing and cutting. It offers flexible toolhead configurations, including options for one, two, or three toolheads. The available toolhead options include a Pellet Extruder, Dual Pellet Extruders, Pellet + Filament Extruder, and Pellet Extruder + Spindle. The Pellet and Filament Extruders operate at 400°C, while the bed is heated to 140°C and the enclosure reaches 80°C. The spindle runs at a speed of 18,000 RPM and can accommodate tools up to 1/4″ in diameter and 4″ in length, with 3-axis sensor-based calibration. The extrusion capabilities include Pellet Nozzle Diameters ranging from 0.6mm to 9.0mm and Filament Nozzle Diameters from 0.4mm to 1.2mm. Pellet throughput ranges from 0.45kg to 13.6kg (1lb to 30lbs) per hour, and Filament throughput is up to 0.9kg (1lb to 2lbs) per hour. The system is powered by a CNC controller and features servo-driven axes, with print speeds up to 0.5m/sec. Optional accessories include integrated pellet and filament dryers, along with HEPA air filtration. The system requires a power input of 208V Three Phase 100A, has a machine weight of 2722kg (6000lbs), and occupies a footprint of 3.35m x 3.05m x 3.05m (11′ x 10′ x 10′).