3D Systems EXT 220 MED (Kumovis R1)

- Home

- Shop

- 3D printer, 3D Systems 3D Printer

- 3D Systems EXT 220 MED (Kumovis R1)

3D Systems EXT 220 MED (Kumovis R1)

THE FIRST 3D PRINTING PLATFORM SPECIFICALLY DESIGNED FOR MEDICAL DEVICE PRODUCTION

The EXT 220 MED, formerly the Kumovis R1, is the only extrusion platform that features an integrated clean room and is validated by leading medical device manufacturers and hospitals worldwide.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

Create high-quality medical parts with the EXT 220 MED (Kumovis R1)

EXT 220 MED (Kumovis R1) – 3D Systems Industrial FDM 3D Printer

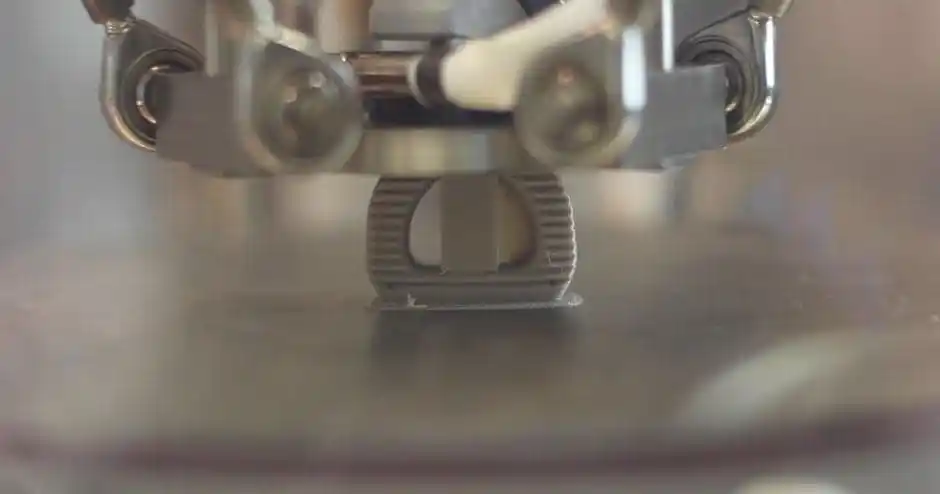

The EXT 220 MED (Kumovis R1) is designed for printing medical materials.

3D print medical devices in high performance polymers with EXT 220 MED

The EXT 220 MED, formerly the Kumovis R1, is an open filament 3D printer designed to enable manufacture of medical devices with implant- and medical-grade polymers like PEEK and Radel® PPSU.

Temperature Management is Key to Excellent Mechanical Properties

The EXT 220 MED is equipped with a global laminar air flow, which allows users to heat the build chamber homogenously up to 250 degrees Celsius. The additional local air flow helps you improve the mechanical properties of your devices. The platform is designed to control temperatures during production. Medical devices produced using thermogenic polymers, like PEEK and Radel® PPSU, are temperature controlled during production resulting in high-quality printed parts.

Fully controllable build chamber heating

Heat up to 250 degrees Celsius, prevent device warping, increase layer adhesion, and adapt build chamber temperature to suit specific polymers

Laminar airflow enabling homogenous temperature distribution

Guarantee reproducibility with no temperature gradient within the build part

Adaptive local temperature management

Adjust local cooling for each strand and layer individually, heat up to further increase layer adhesion, reduce the need for post-processing, and simplify removal of support structures

Heat up to 250 degrees Celsius, prevent device warping, increase layer adhesion, and adapt build chamber temperature to suit specific polymers

Make the Build Chamber a Clean Room

With the help of the integrated filter system, the build chamber can be turned into a clean room to avert contamination. What’s more, the 3D printer is “clean room ready” for production in existing sterile environments and meets medical standards.

The TYPE EXT 220 MED utilizes Fused Layer Manufacturing (FLM) technology, processing polymer filament for layer-by-layer part production. Its dimensions are 823 x 985 x 1950 mm (32.4 x 38.8 x 76.8 in.), and it offers a max build envelope of Ø220 x 160 mm (Ø8.7 x 6.3 in.). Typical materials include PEEK, PEKK, Radel® PPSU, PEEK CFR, and biodegradable polymers, with a layer thickness range of 0.1 – 0.3 mm (0.004 – 0.012 in.). The filament diameter is 1.75 mm (0.069 in.) and the nozzle diameter is 0.4 mm (0.016 in.), with optional 0.2/0.6 mm sizes. Print speeds range from 100 – 4000 mm/min (4 – 157.5 in./min), with a max movement speed of 9000 mm/min (354 in./min). The machine weighs 450 kg (1102 lbs.) and requires electrical input of 380 – 400VAC, 3PH, 15A, 50-60Hz. Compressed air needs are 40 LPM (5-10 BAR) or 85 SCFH (80-140 PSI). The machine supports Ethernet connectivity and operates at maximum nozzle, build plate, and chamber temperatures of 500°C (932°F), 300°C (572°F), and 250°C (482°F), respectively. It features an integrated HEPA filter system for clean room environments (ISO 14644 – Class 7), is suitable for clean room operation, and holds CE, UL, and CSA certifications. The machine comes with a 1-year warranty under 3D Systems’ purchase terms and conditions.