Formlabs Grey Resin Cartridge 1L

- Home

- Shop

- Resins, Standard Resins

- Formlabs Grey Resin Cartridge 1L

Formlabs Grey Resin Cartridge 1L

Standard Resins are general-purpose SLA materials: quality surface finish, details, and minimal post-processing labor.

Supports print resolutions: 160, 100, 50, and 25 microns.

No post-curing required.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

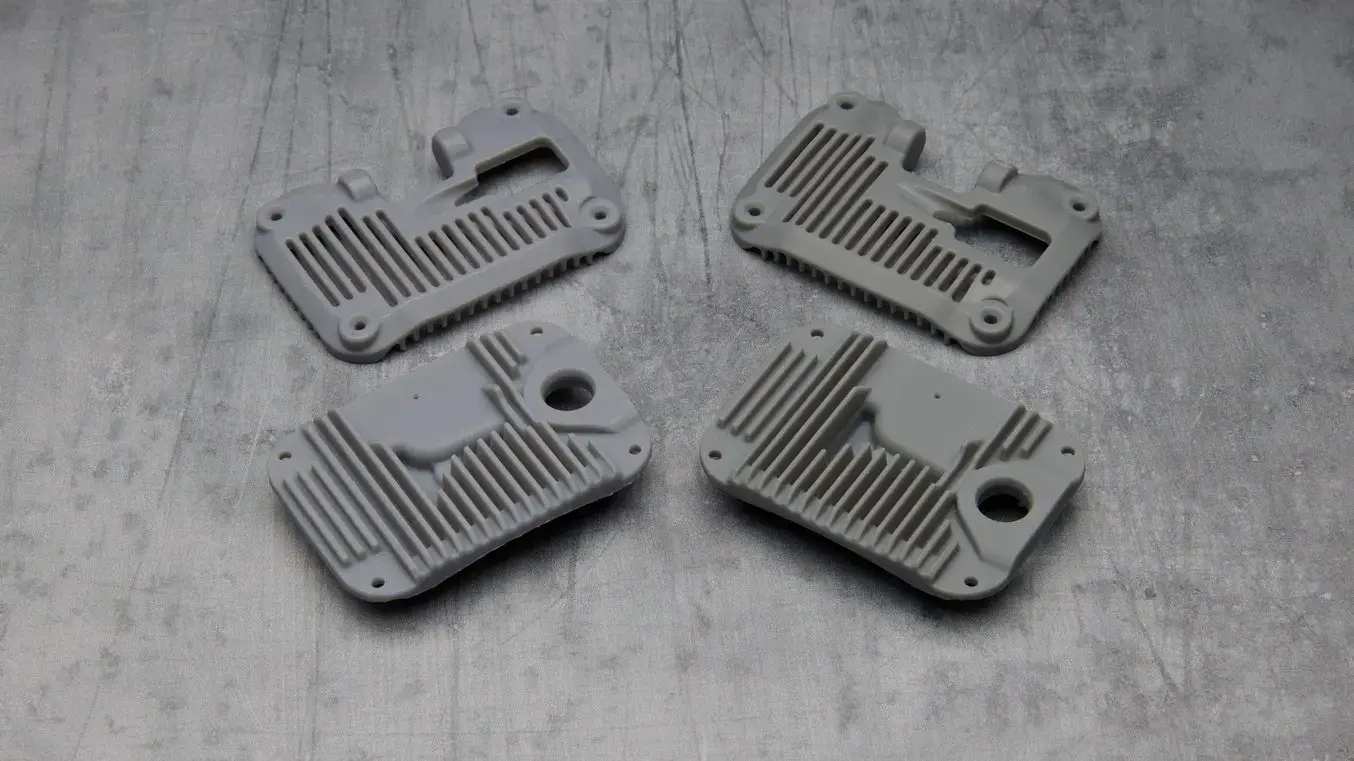

Formlabs Grey Resin V4 1L – High Detail and Versatility

Reliable grey resin for detailed prints and prototypes.

Formlabs Grey Resin V4 1L offers a great balance of detail and versatility, making it suitable for a wide range of applications,

from prototyping to end-use parts. Its neutral color allows for easy finishing and painting.

DOCUMENT TDS.PDF

Grey Resin V4

Product Description

Grey Resin is perfect for general-purpose prototyping and design, and models with intricate details. With a matte surface finish, opaque appearance, and precise details, prints are ready to use right off the printer. Its neutral undertone makes a great base for parts that will eventually be painted or undergo other finishing processes.

Grey Resin V4 is compatible with Form 3 and Form 2 Series printers. Choose Grey Resin V5 on the Form 4 Series for three times faster print speed and improved mechanical properties.

Applications for Grey Resin

Create dimensionally accurate parts that are stiff and strong with unmatched print reliability.

Consider Grey Resin for:

Form and fit prototyping

General dental models

Presentation-ready models with fine features and intricate details

Jigs and fixtures

Material Properties Data

| Property | Green | Post-Cured | Green (Imperial) | Post-Cured (Imperial) | Method |

|---|---|---|---|---|---|

| Tensile Properties | |||||

| Ultimate Tensile Strength | 38 MPa | 65 MPa | 5510 psi | 9380 psi | ASTM D 638-10 |

| Tensile Modulus | 1.6 GPa | 2.8 GPa | 234 ksi | 402 ksi | ASTM D 638-10 |

| Elongation at Failure | 12 % | 6.2 % | 12 % | 6.2 % | ASTM D 638-10 |

| Flexural Properties | |||||

| Flexural Modulus | 1.25 GPa | 2.2 GPa | 181 ksi | 320 ksi | ASTM C 790-10 |

| Impact Properties | |||||

| Notched IZOD | 16 J/m | 25 J/m | 0.3 ft-lbf/in | 0.46 ft-lbf/in | ASTM D 256-10 |

| Temperature Properties | |||||

| Heat Deflection Temp. @ 264 psi | 42.7 °C | 58.4 °C | 108.9 °F | 137.1 °F | ASTM D 648-07 |

| Heat Deflection Temp. @ 66 psi | 49.7 °C | 73.1 °C | 121.5 °F | 163.6 °F | ASTM D 648-07 |