Original Prusa MK4S

- Home

- Shop

- 3D printer, Prusa 3D Printer

- Original Prusa MK4S

Original Prusa MK4S

฿55,640.00 Inc. VAT

The Original Prusa MK4 S features a new 32-bit connected architecture and an advanced Nextruder for flawless first layers without Live Adjust Z. Enjoy high-speed printing with Input Shaper and Pressure Advance, enhanced safety features, and convenient extras like quick-swap nozzles, remote printing/webcam support, all in a remarkably quiet package.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

Original Prusa MK4S – High-Quality 3D Printing Solution

Advanced, user-friendly 3D printer for precise results

The Original Prusa MK4S is a top-tier 3D printer, offering precise and reliable printing with user-friendly controls.

Designed for hobbyists and professionals alike, it delivers consistent, high-quality prints.

VIDEO

.elementor-57645 .elementor-element.elementor-element-bad4030 > .elementor-container > .elementor-column > .elementor-widget-wrap{align-content:flex-start;align-items:flex-start;}.elementor-57645 .elementor-element.elementor-element-bad4030 > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-57645 .elementor-element.elementor-element-baf99ae > .elementor-container > .elementor-column > .elementor-widget-wrap{align-content:center;align-items:center;}.elementor-57645 .elementor-element.elementor-element-181c227 > .elementor-container > .elementor-column > .elementor-widget-wrap{align-content:flex-start;align-items:flex-start;}.elementor-57645 .elementor-element.elementor-element-46c2b5f > .elementor-container > .elementor-column > .elementor-widget-wrap{align-content:flex-start;align-items:flex-start;}

การพิมพ์ความเร็วสูงอย่างง่ายดาย

ด้วยการใช้เทคโนโลยี Input Shaper และ Pressure Advance ที่เราพัฒนาในเฟิร์มแวร์ของ MK4 เครื่องพิมพ์สามารถกำจัดการสั่นสะเทือนในงานพิมพ์และคาดการณ์การไหลของเส้นวัสดุ ส่งผลให้เวลาการพิมพ์ลดลงมากถึง 70% เมื่อเทียบกับ MK3 และที่สำคัญ เครื่องทำงานได้อย่างเงียบแม้ในความเร็วสูง ลองชมวิดีโอการพิมพ์ Benchy ในเวลาน้อยกว่า 20 นาทีได้เลย

ชั้นแรกที่สมบูรณ์แบบทันทีจากกล่อง

ด้วยเซนเซอร์ Loadcell ที่มีความแม่นยำ MK4 สามารถพิมพ์ชั้นแรกได้อย่างเรียบเนียนและสม่ำเสมอโดยอัตโนมัติ โดยไม่ต้องให้ผู้ใช้ปรับตั้งค่าเอง เครื่องจะเคาะแผ่นพิมพ์ด้วยหัวฉีดในรูปแบบตารางเพื่อวัดระยะห่างและคำนวณค่าชดเชยที่เหมาะสม ผลลัพธ์คือชั้นแรกที่สมบูรณ์แบบบนทุกพื้นผิวโดยไม่ต้องปรับตั้งค่าด้วยมือ

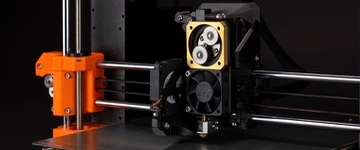

Nextruder พร้อม Breakout Board

หัวฉีดคือหัวใจของเครื่องพิมพ์ 3 มิติ และหัวฉีดนี้เป็นพิเศษ เครื่องพิมพ์ส่วนใหญ่ในปัจจุบัน การเปลี่ยนชิ้นส่วนของหัวฉีดเป็นกระบวนการที่ซับซ้อน แต่ด้วย Breakout Board ใหม่ใน Nextruder ชิ้นส่วนต่าง ๆ เช่น พัดลม, ฮีตเตอร์, เทอร์มิสเตอร์ ฯลฯ จะเชื่อมต่อได้โดยตรง ทำให้การเปลี่ยนชิ้นส่วนทำได้ภายในเวลาไม่กี่นาที

ชั้นแรกที่สมบูรณ์แบบทันทีจากกล่อง

ด้วยเซนเซอร์ Loadcell ที่มีความแม่นยำ MK4 สามารถพิมพ์ชั้นแรกได้อย่างเรียบเนียนและสม่ำเสมอโดยอัตโนมัติ โดยไม่ต้องให้ผู้ใช้ปรับตั้งค่าเอง เครื่องจะเคาะแผ่นพิมพ์ด้วยหัวฉีดในรูปแบบตารางเพื่อวัดระยะห่างและคำนวณค่าชดเชยที่เหมาะสม ผลลัพธ์คือชั้นแรกที่สมบูรณ์แบบบนทุกพื้นผิวโดยไม่ต้องปรับตั้งค่าด้วยมือ

คุณภาพงานพิมพ์ที่ยอดเยี่ยม

MK4 มาพร้อมกับชิ้นส่วนพลาสติกที่ออกแบบใหม่ให้แข็งแรงกว่าเดิมและมอเตอร์สเต็ปเปอร์ที่มีความแม่นยำ 0.9° ในแกน X และ Y ที่ช่วยลดการเกิดลายละเอียดในชิ้นงาน นอกจากนี้ยังมีแกน Z ที่หนาขึ้นถึง 10 มม. ผลลัพธ์คือ งานพิมพ์มีคุณภาพดีขึ้นกว่าเดิม และการพิมพ์ด้วยเส้นวัสดุที่พิมพ์ยาก เช่น Flex ก็ทำได้ง่าย

หน้าจอ LCD สีและ UI ที่ใช้งานง่าย

หน้าจอของ MK4 รองรับภาพขนาดย่อของ G-code, QR code และองค์ประกอบอื่น ๆ ที่ทำให้การใช้งานเครื่องง่ายขึ้น เราได้ออกแบบเมนูหลายเมนูใหม่และเพิ่มแถบฟุตเตอร์ที่สามารถปรับแต่งได้ ใต้หน้าจอ LCD มีแถบสถานะ RGB เพื่อแสดงสถานะปัจจุบันของเครื่องพิมพ์ และมีพอร์ต USB-A สำหรับใช้กับแฟลชไดรฟ์ USB

Technical Parameters

| Measurements | |

|---|---|

| Build Volume | 250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in |

| Filament diameter | 1.75 mm |

| Layer height | 0.05-0.30 mm |

| Printer dimensions (without spool) | 7 kg, 500×550×400 mm; 19.6×21.6×15.7 in (X×Y×Z) |

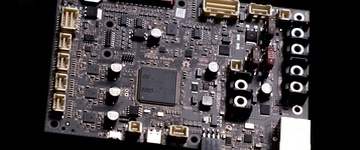

| Electronics | |

| Mainboard | Custom 32-bit xBuddy electronics with STM32 |

| Stepper Drivers | Trinamic 2130 |

| Stepper motors | Precise 0.9° X,Y stepper motors (prevents VFA) |

| Extruder | |

| Extruder | Nextruder, Direct Drive, E3D V6 compatible (with adapter) |

| Extruder electronics | Custom breakout board for connecting fans, thermistors and other parts. |

| Filament path | Aluminum heatsink, all-metal hotend |

| Drive system | Nextruder Planetary Gear System, 10:1 gearbox ratio |

| Cooling fan | High-performance turbine, 360° cooling system |

| Nozzle | High-flow Prusa Nozzle brass CHT – 0.4 mm |

| Max. operating temperature | |

| Max nozzle temperature | 290 °C / 554 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| Controls | |

| LCD screen | 3.5″ graphic 65k color screen |

| Connectivity | NFC receiver, optional ESP Wi-Fi module (delivered with the printer) |

| Print medium | USB drive / LAN / internet via Prusa Connect |

| Sensors | |

| Advanced sensors | Filament sensor, Loadcell sensor, Power panic, 4 high-precision thermistors (genuine Semitec) + fan motors RPM monitoring |

| Print surface | |

| Print surface | Magnetic heatbed with removable PEI spring steel sheets |

| Calibration | |

| Bed calibration | Automatic, Mesh Bed Leveling (only on print area) |

| Materials | |

| Supported materials | PLA, PETG, Flex, PVA, PC, PP, CPE, PVB and when using the Original Prusa Enclosure with filtration add-on ABS, ASA, HIPS, PA |

| Power | |

| PSU | 240W, custom made by Delta with Power Panic HW |

| Power consumption | PLA settings: 80W / ABS settings: 120W |