Pollen New Pam Series P HT

- Home

- Shop

- 3D printer, Pollen 3D Printers

- Pollen New Pam Series P HT

Pollen New Pam Series P HT

Is a high-performance 3D printer designed for precision and versatility. Featuring dual extruders and a large print volume of Ø 300 x H 300 mm, it supports a wide range of materials, including high-performance, standard, and TPE filaments. With a printing resolution of 40µm (Z) and 5µm (X,Y), it ensures exceptional detail and accuracy. The printer also offers a heated room, radiant disc, and customizable print bed options, making it ideal for demanding industrial applications. It is compatible with Honeyprint and Cura software by Pollen AM for easy and efficient printing management.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

Pollen New Pam Series P HT – High-Temp Pellet 3D Printing

High-temperature pellet 3D printing for industrial use

The Pollen Pam Series P HT is engineered to handle high-temperature materials, making it ideal for industrial applications requiring durability and precision.

Its versatility in material choice and print quality makes it a top choice for advanced manufacturing.

New Pam Series P

Polymer Additive Manufacturing

Precision Robustness Repeatability

For demanding industries

New Pam Series P HT is using performance thermoplastics taking special care of high temperatures.

Dedicated to advanced applications, New Pam Series P HT is pushing engineering challenges forwards.

New print head

Our interlayer heating device is designed to increase Z direction mechanical performances. It keeps a warm zone over the part and preserve good adhesion between each layer.

A new high sheer extruder is dedicated to semi-cristallin materials for better flow control.

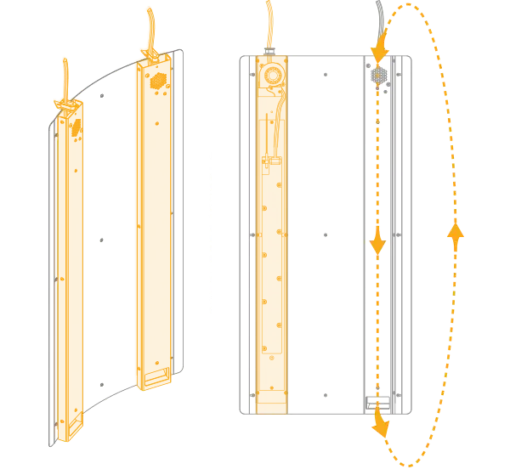

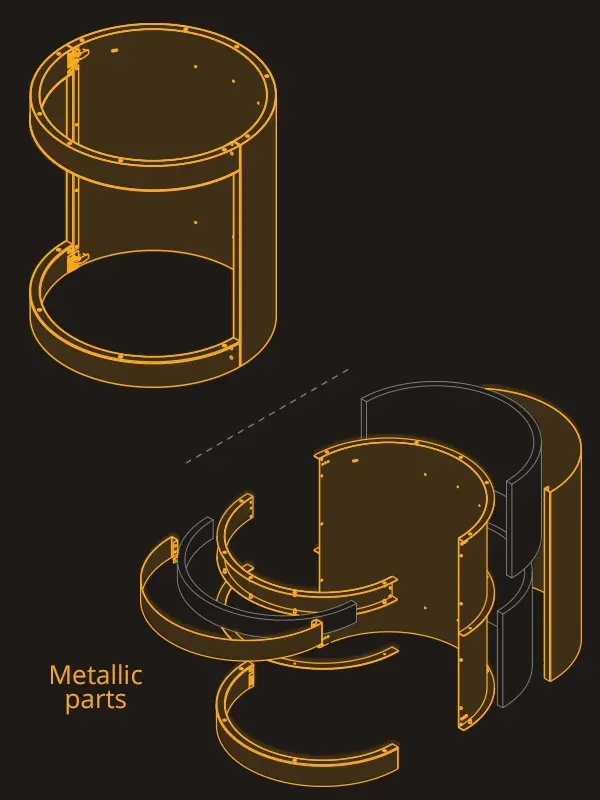

New frame and casing

The build volume is enhanced with new metallic casing and new heat

treatment for high temperature materials.

New heating room

Specially designed forced convection heating room device: hot air is recycled from inside the build volume for increased thermal regularity.

Heating room temperature control is integrated in Honeyprint software for easy set-up. The maximum temperature is 80°C.

New metal skin

New Pam Series P HT has a brand new metallic and insulated casing. Our team has developed the original wooden casing with great insulation performances without additive heated build chamber.

In regards of improving thermal regulation and increasing maximum room temperature we completely rethought our position towards new casing materials. Insulation plates are made out of glass wools and overlapping casing is in aluminum. This enables the best heating performances for the build volume and rapid rise in temperature.

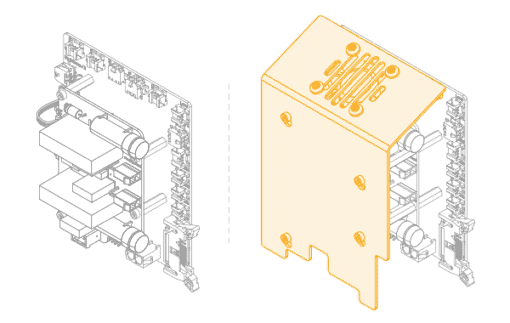

New electronics

The electronics benefit from the same improvement as New Pam Series P with two extruder boards and new wiring. In order to increase robustness and fine control over extruder boards, a specific casing and cooling is necessary.

Main specifications

| Main Specifications | Details |

|---|---|

| 3D Printing Process | PAM |

| Number of Extruders | 2 |

| Compatible Materials | High performance, performance, standard & TPE materials |

| Print Volume | Ø 300 x H 300 mm |

| Printing Resolution | 40µm (Z) and 5µm (X,Y) |

| Heating Room | Up to 80°C |

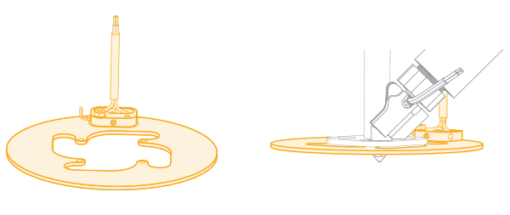

| Radiant Disc | Up to 300°C |

| Print Bed | 150°C and 250°C options |

| Supplied Software | Honeyprint & Cura by Pollen AM |