Pollen Pam Series MC

- Home

- Shop

- Pollen 3D Printers, 3D printer, Metal 3D Printer

- Pollen Pam Series MC

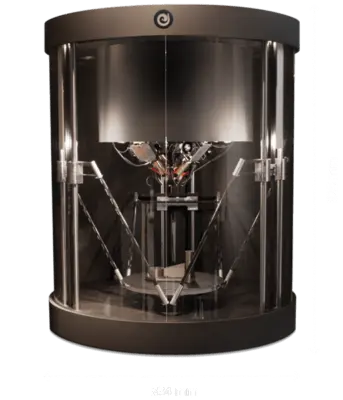

Pollen Pam Series MC

Is a high-performance 3D printing solution designed for metal and ceramic feedstocks. Offering precise control over print quality, it supports up to four extruders and provides maximum print volumes of Ø 300 x H 300 mm. With a range of nozzle sizes and high extrusion temperatures up to 450°C, the system is ideal for creating complex metal and ceramic parts. Its advanced features, including a heated room and radiant disc, ensure optimal printing conditions, while the software integration with Honeyprint and Cura by Pollen AM enhances ease of use and efficiency.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

Pollen Pam Series MC – Multi-Material 3D Printing

Multi-material capabilities for advanced applications

The Pollen Pam Series MC is a multi-material 3D printer that provides advanced versatility for various industrial applications.

Its capability to work with a range of materials, including composites, ensures precision and durability in manufacturing.

Pam Series MC

Metal & Ceramic Additive Manufacturing

Easy & safe operability

Rentability

Flexibility and freedom

Print head

– High shear extruders

– Interlayer radiant heater

Build plate

– Up to 150°C heat resistance

– Up to 250°C build platform option

Material cartridge

– High temperature feeder

Frame and casing

– Heated build volume

– Metallic insulated casing

Electronic and software

– Enhanced cooling

– Fine-tuned temperature control

Main specifications

| Main Specifications | Details |

|---|---|

| 3D Printing Process | PAM |

| Number of Extruders | 2 to 4 |

| Compatible Materials | Metal & Ceramic feedstocks (Injection moulding grades) |

| Maximum Print Volume | Ø 300 x H 300 mm |

| Nozzle Sizes | Ø 0.25 – 0.40 – 0.60 – 0.80 – 1.00 – 1.20 |

| Stepper Motor Resolution | 40µm (Z) and 5µm (X,Y) |

| Maximum Extrusion Temperature | 450°C |

| Maximum Print Bed Temperature | 150°C and 250°C options |

| Heating Room | Up to 70°C |

| Radiant Disc | Up to 300°C |

| Supplied Software | Honeyprint & Cura by Pollen AM |