Formlabs Rigid 10K Resin Cartridge 1L

- Home

- Shop

- Resins, Engineering Resins

- Formlabs Rigid 10K Resin Cartridge 1L

Formlabs Rigid 10K Resin Cartridge 1L

Choose Rigid 10K Resin for precise industrial parts that need to withstand significant load without bending. Rigid 10K Resin exhibits a smooth matte finish and is highly resistant to heat and chemicals. The “10K” in the name represents the material’s tensile modulus.

Supports print resolutions: 100 and 50 microns. Post-curing required.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

Rigid 10K Resin 1L – Ultra High Stiffness Material

Formlabs Rigid 10K Resin for ultra-rigid parts

Rigid 10K Resin 1L provides the highest stiffness in the Formlabs range, ideal for industrial applications that require maximum rigidity and strength.

Suitable for printing jigs, fixtures, and manufacturing aids.

DOCUMENT TDS.PDF

Rigid 10K Resin

Product Description

Whether you’re optimizing your manufacturing process, rapidly iterating through designs, or assessing form, fit, and function, Formlabs Engineering Resins are formulated to withstand extensive testing and perform under stress.

This highly glass-filled resin is the stiffest material in our engineering portfolio. Choose Rigid 10K Resin for precise industrial parts that need to withstand significant load without bending. Rigid 10K Resin exhibits a smooth matte finish and is highly resistant to heat and chemicals.

The “10K” in the name represents the material’s tensile modulus. If you need a less stiff material, try Rigid 4000 Resin

Supports print resolutions: 100 and 50 microns. Post-curing required.

Why Choose Rigid 10K Resin?

Rigid 10K Resin is a high performance material that is strong, completely stiff, and stable.

Extremely Stiff

Resistant to deformation under a variety of forces, pressures, and torques.High Thermal and Chemical Resistance

Withstands high temperatures and a variety of chemicals.Precise

Produce strong, detailed, and accurate molds or models.Incredible Surface Quality

Exhibits a smooth matte finish.

Applications

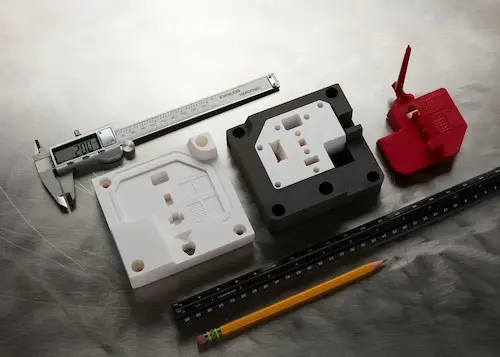

Rigid 10K Resin is ideal for creating rigid, strong, industrial-grade prototypes. Rigid 10K Resin can be faster and easier to print compared to milling aluminum and steel.

Consider Rigid 10K Resin for:

Short-run injection mold masters and inserts

Heat resistant and fluid exposed components, jigs, and fixtures

Aerodynamic test models

Simulates stiffness of glass and fiber-filled thermoplastics

Material Properties*

| Material Properties | Rigid 10K Resin |

|---|---|

| Ultimate Tensile Strength | 88 MPa |

| Tensile Modulus | 11 GPa |

| Elongation | 1.7% |

| Flexural Modulus | 9.9 GPa |

| Notched Izod | 20 J/m |

| Heat Deflection Temp. @ 0.45 MPa | 238 °C |

| Thermal Expansion, 0-150 °C | 41 μm/m/°C |