Which one should you choose: SLA 3D Printer or FDM 3D Printer?

- Home

- Articles

- 3D Printing News, Article

- Which one should you choose: SLA 3D Printer or FDM 3D Printer?

Which one should you choose: SLA 3D Printer or FDM 3D Printer?

This post is also available in: ไทย (Thai) 日本語 (Japanese)

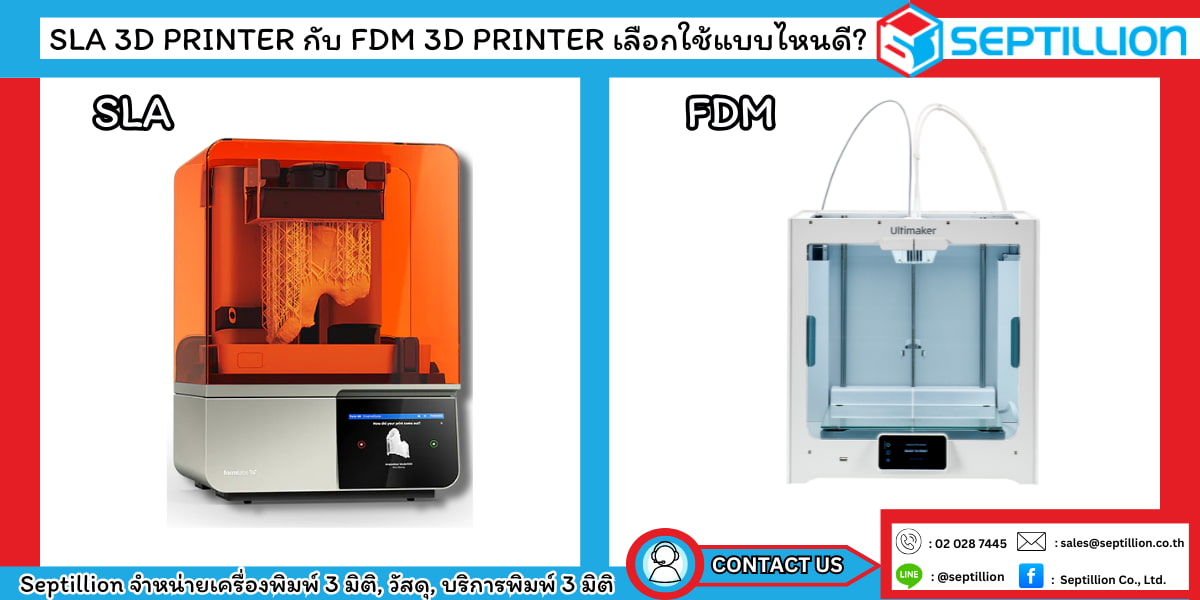

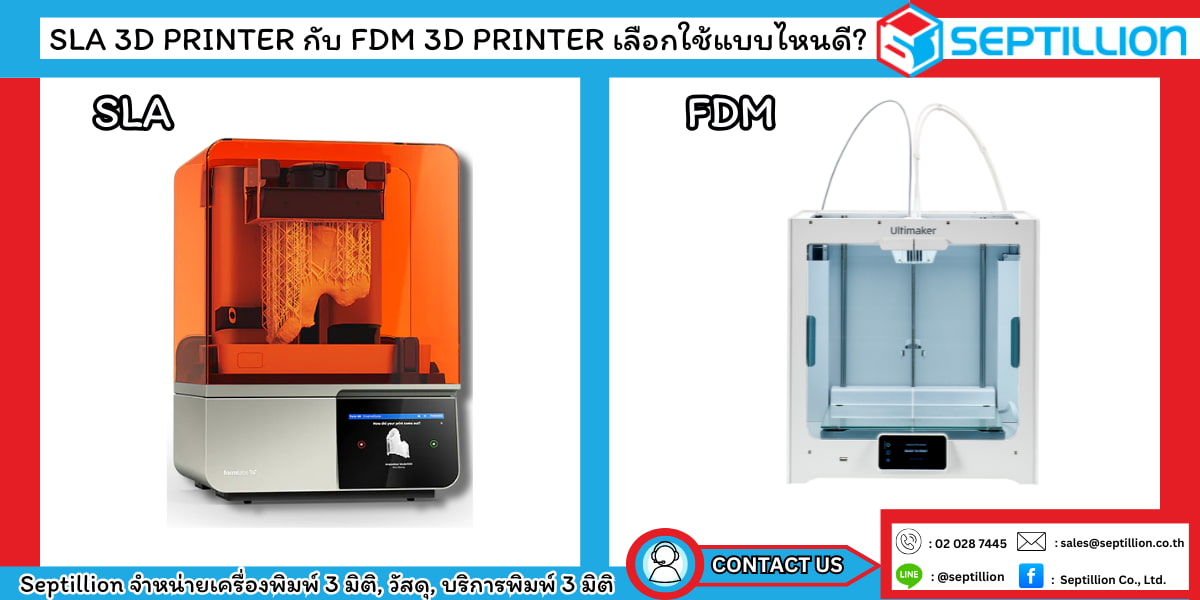

SLA 3D Printer and FDM 3D Printer

In the current time, 3D printers play a significant role in prototyping and manufacturing across various industries. As a result, 3D printing technology continues to evolve. Among the most popular technologies are SLA and FDM, each with its own strengths and limitations. This article summarizes the key differences between SLA and FDM and offers guidance on choosing the right technology for your 3D printing needs.

Understanding SLA and FDM 3D Printers

SLA (Stereolithography) is a type of Vat Photopolymerisation 3D printing technology that uses light to solidify liquid resin into a 3D object. On the other hand, FDM (Fused Deposition Modeling) is a type of Material Extrusion technology that extrudes melted material through a nozzle layer by layer. FDM is widely popular due to its versatility in producing a range of parts. Let’s get to know SLA 3D Printer and FDM 3D Printer as follows:

SLA 3D Printers

SLA 3D printers use ultraviolet (UV) light to cure liquid resin in a tank into solid parts. SLA 3D printer repeats the process layer by layer until the object is complete. The resin used is a liquid photopolymer that reacts to UV light through a chemical reaction known as polymerization.

Advantages and Limitations of SLA:

The polymerization process results in extremely high-resolution prints with smooth surfaces, where layer lines are nearly invisible to the naked eye—superior to other 3D printing methods like FDM. This makes SLA ideal for creating molds, models, jewelry, and any design requiring fine details.

Unlike FDM, SLA does not use a nozzle, so the resolution is not limited by nozzle diameter. Instead, it is determined by the laser spot size. However, SLA printing is generally slower than FDM due to the high level of detail per layer.

FDM 3D Printers

FDM 3D printers operate using an additive process that builds objects layer by layer using thermoplastic filaments such as PLA, ABS, or PETG. The filament is melted by heat and extruded through a nozzle to form each layer. The diameter of the nozzle directly affects print resolution—smaller nozzles yield finer details but take more time.

Advantages and Limitations of FDM:

FDM is known for its speed and cost-effectiveness. It is a popular choice for rapid prototyping and low-cost production. However, FDM prints generally have lower resolution than SLA. To achieve a smoother finish, post-processing such as sanding or coating may be required. It’s ideal for producing affordable models or functional prototypes for design validation.

Choosing Between SLA and FDM

When deciding between SLA and FDM, consider key factors such as the required print resolution and available budget. Expert consultation can also help ensure that your prints meet expectations. At Septillion, we offer free consultation and expert support from experienced engineers. You can also visit us to see the printers in action and test your prints before making a decision.

Recommended SLA & FDM Printers from Trusted Brands

Formlabs is highly regarded in the industry and by professionals for offering advanced 3D printers with several advantages over other technologies like FDM and DLP.

- High Resolution and Print Quality

Stereolithography (SLA) uses laser light to cure resin layer by layer, delivering sharp details and smooth surfaces. It offers resolutions as fine as 25 microns—much finer than most FDM printers, which typically produce visible layer lines.

- High-Quality Resin Materials for Every Application

Formlabs offers a wide variety of resins, including Standard, Tough, Durable, Elastic, Rigid, Castable, Biocompatible, and Dental Resins—suitable for everything from engineering prototypes and jewelry to dental and medical tools.

- User-Friendly and Smart Software

PreForm software automatically optimizes print files, and the One-Click Print feature allows even beginners to start printing with ease.

- High-Quality Resin Materials for Every Application

Formlabs offers a wide variety of resins, including Standard, Tough, Durable, Elastic, Rigid, Castable, Biocompatible, and Dental Resins—suitable for everything from engineering prototypes and jewelry to dental and medical tools.

- Precision and Print Consistency

Formlabs printers use a high-precision laser with a spot size of just 85 microns, ensuring excellent accuracy. The Low Force Stereolithography (LFS) system reduces peel forces during printing, improving results for thin or complex parts.

- Automation for Faster Workflow

Form Wash and Form Cure automate the washing and curing process, reducing manual labor. New models like the Form 3+ and Form 3L feature easy-to-swap resin tanks and build platforms.

On sale products

-

Formlabs Castable Wax 40 Resin 1L

-

SpiderMaker Matte PLA 700g.

฿1,594.30Original price was: ฿1,594.30.฿1,090.00Current price is: ฿1,090.00. Inc. VAT -

Zortrax Z-Semiflex Filament Black 1.75mm. 800g.

฿3,691.50 Inc. VAT