Formlabs Form 3L

- Home

- Shop

- 3D printer, Formlabs 3D Printers

- Formlabs Form 3L

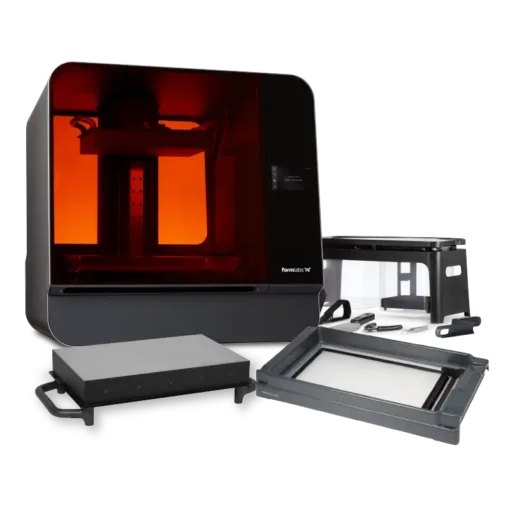

Formlabs Form 3L

฿613,110.00 Inc. VAT

The Formlabs Form 3L is a large-format SLA 3D printer designed for high-precision industrial-grade prints. Perfect for producing large, detailed parts with exceptional reliability, it’s ideal for engineering, healthcare, and manufacturing applications.

What’s Included

- Form 3L 3D Printer

- Form 3L Resin Tank V3

- Form 3L Build Platform

- Form 3L Finish Kit: Cleaning Tools

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

Formlabs Form 3L

With a large build volume of 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in),

you can print full-scale bulky prototypes or detailed models.

Take control of large-format prototyping and bring your biggest ideas to life with the Form 3L, a cost-effective large scale 3D printer that doesn’t compromise on the details.

.elementor-67277 .elementor-element.elementor-element-c1a17f1 > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-bc-flex-widget .elementor-67277 .elementor-element.elementor-element-376178b.elementor-column .elementor-widget-wrap{align-items:center;}.elementor-67277 .elementor-element.elementor-element-376178b.elementor-column.elementor-element[data-element_type=”column”] > .elementor-widget-wrap.elementor-element-populated{align-content:center;align-items:center;}.elementor-67277 .elementor-element.elementor-element-aab4028 > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-67277 .elementor-element.elementor-element-8be411f > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-67277 .elementor-element.elementor-element-584410c .elementor-image-box-wrapper{text-align:left;}.elementor-67277 .elementor-element.elementor-element-584410c.elementor-position-right .elementor-image-box-img{margin-left:15px;}.elementor-67277 .elementor-element.elementor-element-584410c.elementor-position-left .elementor-image-box-img{margin-right:15px;}.elementor-67277 .elementor-element.elementor-element-584410c.elementor-position-top .elementor-image-box-img{margin-bottom:15px;}.elementor-67277 .elementor-element.elementor-element-584410c .elementor-image-box-wrapper .elementor-image-box-img{width:45%;}.elementor-67277 .elementor-element.elementor-element-584410c .elementor-image-box-img img{transition-duration:0.3s;}.elementor-67277 .elementor-element.elementor-element-c657df8 .elementor-image-box-wrapper{text-align:left;}.elementor-67277 .elementor-element.elementor-element-c657df8.elementor-position-right .elementor-image-box-img{margin-left:15px;}.elementor-67277 .elementor-element.elementor-element-c657df8.elementor-position-left .elementor-image-box-img{margin-right:15px;}.elementor-67277 .elementor-element.elementor-element-c657df8.elementor-position-top .elementor-image-box-img{margin-bottom:15px;}.elementor-67277 .elementor-element.elementor-element-c657df8 .elementor-image-box-wrapper .elementor-image-box-img{width:30%;}.elementor-67277 .elementor-element.elementor-element-c657df8 .elementor-image-box-img img{transition-duration:0.3s;}.elementor-67277 .elementor-element.elementor-element-b830930 .elementor-image-box-wrapper{text-align:left;}.elementor-67277 .elementor-element.elementor-element-b830930.elementor-position-right .elementor-image-box-img{margin-left:15px;}.elementor-67277 .elementor-element.elementor-element-b830930.elementor-position-left .elementor-image-box-img{margin-right:15px;}.elementor-67277 .elementor-element.elementor-element-b830930.elementor-position-top .elementor-image-box-img{margin-bottom:15px;}.elementor-67277 .elementor-element.elementor-element-b830930 .elementor-image-box-wrapper .elementor-image-box-img{width:30%;}.elementor-67277 .elementor-element.elementor-element-b830930 .elementor-image-box-img img{transition-duration:0.3s;}.elementor-67277 .elementor-element.elementor-element-71e6686{–spacer-size:50px;}.elementor-67277 .elementor-element.elementor-element-683c6de > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-67277 .elementor-element.elementor-element-f7a9372 > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-67277 .elementor-element.elementor-element-a7ffbd8 .elementor-repeater-item-2013c71 .swiper-slide-bg{background-color:#bbbbbb;background-image:url(http://septillion.co.th/wp-content/uploads/01162020_optimus_ride_loc_208_1.webp);background-size:cover;}.elementor-67277 .elementor-element.elementor-element-a7ffbd8 .elementor-repeater-item-2013c71 .elementor-background-overlay{background-color:rgba(0,0,0,0.5);}.elementor-67277 .elementor-element.elementor-element-a7ffbd8 .elementor-repeater-item-03403fb .swiper-slide-bg{background-color:#bbbbbb;background-image:url(http://septillion.co.th/wp-content/uploads/quote_continental.webp);background-size:contain;}.elementor-67277 .elementor-element.elementor-element-a7ffbd8 .elementor-repeater-item-03403fb .elementor-background-overlay{background-color:rgba(0,0,0,0.5);}.elementor-67277 .elementor-element.elementor-element-a7ffbd8 .elementor-repeater-item-9aa2ea0 .swiper-slide-bg{background-color:#833ca3;background-image:url(http://septillion.co.th/wp-content/uploads/01162020_optimus_ride_loc_208_12x.webp);background-size:contain;}.elementor-67277 .elementor-element.elementor-element-a7ffbd8 .elementor-repeater-item-9aa2ea0 .elementor-background-overlay{background-color:rgba(0,0,0,0.5);}.elementor-67277 .elementor-element.elementor-element-a7ffbd8 .swiper-slide{transition-duration:calc(5000ms*1.2);height:400px;}.elementor-67277 .elementor-element.elementor-element-a7ffbd8{width:var( –container-widget-width, 125.508% );max-width:125.508%;–container-widget-width:125.508%;–container-widget-flex-grow:0;}.elementor-67277 .elementor-element.elementor-element-a7ffbd8 .swiper-slide-contents{max-width:100%;}.elementor-67277 .elementor-element.elementor-element-a7ffbd8 .swiper-slide-inner{text-align:center;}.elementor-67277 .elementor-element.elementor-element-78f8d63 > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-bc-flex-widget .elementor-67277 .elementor-element.elementor-element-188bbc8.elementor-column .elementor-widget-wrap{align-items:center;}.elementor-67277 .elementor-element.elementor-element-188bbc8.elementor-column.elementor-element[data-element_type=”column”] > .elementor-widget-wrap.elementor-element-populated{align-content:center;align-items:center;}.elementor-67277 .elementor-element.elementor-element-72ae73a > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-bc-flex-widget .elementor-67277 .elementor-element.elementor-element-f0e33b2.elementor-column .elementor-widget-wrap{align-items:center;}.elementor-67277 .elementor-element.elementor-element-f0e33b2.elementor-column.elementor-element[data-element_type=”column”] > .elementor-widget-wrap.elementor-element-populated{align-content:center;align-items:center;}.elementor-67277 .elementor-element.elementor-element-03946f4 > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-bc-flex-widget .elementor-67277 .elementor-element.elementor-element-1533be2.elementor-column .elementor-widget-wrap{align-items:center;}.elementor-67277 .elementor-element.elementor-element-1533be2.elementor-column.elementor-element[data-element_type=”column”] > .elementor-widget-wrap.elementor-element-populated{align-content:center;align-items:center;}.elementor-67277 .elementor-element.elementor-element-01433c9{–spacer-size:50px;}.elementor-bc-flex-widget .elementor-67277 .elementor-element.elementor-element-200f62f.elementor-column .elementor-widget-wrap{align-items:center;}.elementor-67277 .elementor-element.elementor-element-200f62f.elementor-column.elementor-element[data-element_type=”column”] > .elementor-widget-wrap.elementor-element-populated{align-content:center;align-items:center;}.elementor-67277 .elementor-element.elementor-element-d52c486 > div.elementor-container{max-width:1200px;–porto-flick-carousel-width:1200px;}.elementor-bc-flex-widget .elementor-67277 .elementor-element.elementor-element-6be85b8.elementor-column .elementor-widget-wrap{align-items:center;}.elementor-67277 .elementor-element.elementor-element-6be85b8.elementor-column.elementor-element[data-element_type=”column”] > .elementor-widget-wrap.elementor-element-populated{align-content:center;align-items:center;}.elementor-bc-flex-widget .elementor-67277 .elementor-element.elementor-element-2a3f949.elementor-column .elementor-widget-wrap{align-items:center;}.elementor-67277 .elementor-element.elementor-element-2a3f949.elementor-column.elementor-element[data-element_type=”column”] > .elementor-widget-wrap.elementor-element-populated{align-content:center;align-items:center;}@media(max-width:767px){.elementor-67277 .elementor-element.elementor-element-584410c .elementor-image-box-img{margin-bottom:15px;}.elementor-67277 .elementor-element.elementor-element-c657df8 .elementor-image-box-img{margin-bottom:15px;}.elementor-67277 .elementor-element.elementor-element-b830930 .elementor-image-box-img{margin-bottom:15px;}}

Form 3L

เครื่องพิมพ์ 3 มิติแบบฟอร์แมตขนาดใหญ่ ที่มีขนาดกะทัดรัดพอเหมาะสำหรับสำนักงานและทนทานเพียงพอสำหรับการใช้งานในโรงงาน

ควบคุมกระบวนการผลิตต้นแบบขนาดใหญ่และนำไอเดียใหญ่ของคุณสู่การสร้างสรรค์ด้วย Form 3L เครื่องพิมพ์ 3 มิติขนาดใหญ่ที่คุ้มค่าทางเศรษฐกิจ ซึ่งไม่ลดทอนในรายละเอียด

Form 3L ได้ถูกแทนที่โดย Form 4L ซึ่งเป็นเครื่องพิมพ์ 3 มิติแบบ MSLA รุ่นถัดไปของเรา ที่พัฒนาและปรับปรุงจากพื้นฐานเดิมในทุกๆ ด้าน

ชิ้นส่วนใหญ่ ไอเดียใหญ่

ด้วยพื้นที่การพิมพ์ขนาดใหญ่ถึง 33.5 × 20 × 30 ซม. (13.2 × 7.9 × 11.8 นิ้ว)

คุณสามารถพิมพ์ต้นแบบขนาดเต็มหรือโมเดลที่มีรายละเอียดสูงได้

หยุดการจ้างงานพิมพ์ขนาดใหญ่จากภายนอก

ทำงานได้เร็วขึ้นด้วยเครื่องพิมพ์ 3 มิติขนาดใหญ่ที่มีความยืดหยุ่นเพียงพอในการนำการผลิตขนาดใหญ่เข้ามาทำในองค์กร

การพิมพ์ขนาดเท่าชีวิตสำหรับไอเดียที่ยิ่งใหญ่กว่าชีวิต

Form 3L มีขนาดใหญ่พอที่จะพิมพ์โมเดลขนาดเท่าชีวิต เช่น ต้นแบบหมวกกันน็อกที่พร้อมให้ทดลองสวมใส่

ความสมบูรณ์แบบที่ขยายขนาดได้

หน่วยประมวลผลแสงความแม่นยำสองตัวภายในเครื่องพิมพ์เรซินขนาดใหญ่นี้ ช่วยให้สามารถรักษาความแม่นยำและรายละเอียดอย่างสม่ำเสมอทั่วทั้งพื้นที่การพิมพ์

วัสดุ

Draft Resin

เวลาการพิมพ์

8 ชั่วโมง

ต้นทุนการพิมพ์

$88

ชิ้นส่วนโดย

Black Diamond Equipment

วัสดุ

Grey Resin

เวลาการพิมพ์

59 ชั่วโมง

ต้นทุนต่อชิ้น

$7

จำนวนต่อการพิมพ์: 20 ชิ้น

ชิ้นส่วนโดย

Formlabs

วัสดุ

Tough 2000 Resin

เวลาการพิมพ์

33 ชั่วโมง

ต้นทุนการพิมพ์

$72

ชิ้นส่วนโดย

Continental

วัสดุ

Grey Resin

เวลาการพิมพ์

52 ชั่วโมง

ต้นทุนการพิมพ์

$87

ชิ้นส่วนโดย

Black Diamond Equipment

วัสดุ

Grey Resin

เวลาการพิมพ์

60 ชั่วโมง

ต้นทุนการพิมพ์

$115

ชิ้นส่วนโดย

Minnetronix

วัสดุ

Grey Resin

เวลาการพิมพ์

23 ชั่วโมง

ต้นทุนต่อชิ้น

$17

จำนวนต่อการพิมพ์: 2 ชิ้น

ชิ้นส่วนโดย

OXO

เมื่อเราได้จ้างงานการพิมพ์กรอบปิดขนาดใหญ่จากภายนอก, เราก็ยังเห็นรอยต่อของแต่ละชั้นอยู่เสมอ แต่กับการพิมพ์ของ Form 3L, ฉันไม่เห็นรอยเหล่านั้นเลย การสามารถปรับแต่งต้นแบบฝาครอบด้านนอกได้อย่างรวดเร็วเพื่อเพิ่มความเรียบร้อยในการออกแบบของเราในขั้นตอนวิจัยและพัฒนา (R&D) นั้นเป็นสิ่งที่มีประโยชน์อย่างมาก

เราเคยใช้งาน Form 3 มาก่อนแล้ว ดังนั้นเราจึงมีความคาดหวังสูงเกี่ยวกับ Form 3L การตั้งค่าเครื่องพิมพ์และเริ่มพิมพ์นั้นเป็นกระบวนการเดียวกันที่ง่ายเหมือนเดิม ทุกชิ้นส่วนที่เราพิมพ์ออกมานั้นมีความแม่นยำและสมบูรณ์แบบชัดเจน Form 3L เป็นอุปกรณ์ที่มีคุณภาพสูงและสามารถตั้งมาตรฐานในด้านความเร็ว ขนาด และคุณภาพได้อย่างชัดเจน

เราสามารถลดต้นทุนการพิมพ์ต้นแบบขนาดเต็มจาก $425 ต่อครั้ง เหลือเพียง $70 ต่อครั้ง (เมื่อเทียบกับการจ้างงานจากภายนอก) ด้วยการประหยัดต้นทุนนี้ Form 3L จะคืนทุนให้กับเราได้ในเวลาเพียงแค่สามเดือน

อินเตอร์เฟซหน้าจอสัมผัสความละเอียดสูง:

หน้าจอสัมผัสขนาด 5.5 นิ้วแบบสีเต็มรูปแบบช่วยลดข้อผิดพลาดและขจัดความจำเป็นในการตรวจสอบเครื่องพิมพ์อย่างต่อเนื่อง

การตั้งค่าการพิมพ์อัตโนมัติ:

ผ่านการทดสอบมาแล้วหลายล้านครั้ง ซอฟต์แวร์เตรียมการพิมพ์ฟรีของเรา PreForm จะแนะนำการวางตำแหน่ง, การรองรับ และการจัดเรียงที่เหมาะสมโดยอัตโนมัติ พร้อมทั้งสามารถปรับแต่งได้ตามต้องการ

พัฒนาอย่างต่อเนื่อง:

เรามั่นใจว่าผลิตภัณฑ์ที่ดีที่สุดจะเติบโตและพัฒนาไปตามกาลเวลา และเรามุ่งมั่นที่จะพัฒนาฮาร์ดแวร์ของเราอย่างต่อเนื่องผ่านการปรับปรุงซอฟต์แวร์

การตรวจสอบจากคลาวด์:

สามารถตรวจสอบและจัดการฟลีทเครื่องพิมพ์ 3 มิติขนาดใหญ่ของคุณจากระยะไกลผ่านแดชบอร์ดออนไลน์

วัสดุพิมพ์ความเร็วสูง:

Draft Resin ช่วยบาลานซ์ระหว่างรายละเอียดและความเร็วเพื่อประหยัดเวลาในการพิมพ์ต้นแบบขนาดใหญ่ และสนับสนุนการทดสอบและปรับปรุงอย่างรวดเร็ว

การซ่อมแซมภาคสนาม:

หน่วยประมวลผลแสง, ลูกกลิ้ง, หน้าต่างออปติก, และส่วนประกอบอื่นๆ สามารถเปลี่ยนได้ภายในองค์กรเพื่อรับประกันการทำงานตลอด 24 ชั่วโมงทุกวัน

พื้นผิวที่เรียบเนียน:

โมเดลที่พิมพ์ด้วย Form 3L มีลักษณะคล้ายชิ้นส่วนที่ผ่านการขึ้นรูปด้วยการฉีดพลาสติกและสามารถทำให้มีความโปร่งแสงสูง เพื่อให้ได้ต้นแบบที่มีลักษณะเหมือนจริง

ความแม่นยำที่สม่ำเสมอ:

ระบบเลเซอร์และกระจกช่วยให้การพิมพ์มีคุณภาพสม่ำเสมอทั่วทั้งพื้นที่การพิมพ์ ด้วยความละเอียดในแกน XY ที่ 25 ไมครอน

วัสดุขั้นสูง:

วัสดุแต่ละชนิดของ Formlabs มาพร้อมกับการตั้งค่าการพิมพ์ที่ได้รับการปรับแต่งเพื่อรับประกันความสำเร็จในการพิมพ์ที่เหนือชั้น และความน่าเชื่อถือ รวมถึงคุณสมบัติทางกล, ทางความร้อน หรือทางชีวภาพที่โดดเด่น

อิสระเต็มที่กับ Open Platform

อิสระเต็มที่กับ Open Platform

เพิ่มความหลากหลายในการใช้งานเครื่องพิมพ์ของคุณด้วยวัสดุจากผู้ผลิตภายนอกที่ได้รับการรับรอง, การตั้งค่าการพิมพ์ที่สามารถปรับแต่งได้, หรือความสามารถในการทดลองใช้เรซินฟอโตพอลิเมอร์ 405 นาโนเมตรที่ยังไม่ได้รับการรับรอง (ตัวเลือกเพิ่มเติม, ใบอนุญาตที่ต้องชำระเงิน)

เปลี่ยนวัสดุได้ภายในไม่กี่นาที

เปลี่ยนวัสดุได้ภายในไม่กี่นาที

หลีกเลี่ยงความยุ่งยากและความยุ่งเหยิงในการล้างวัสดุ ด้วยระบบตลับหมึกที่สามารถสลับวัสดุได้ ซึ่งสามารถใช้ร่วมกับเครื่องพิมพ์ SLA รุ่นอื่นๆ ของ Formlabs ได้

การจ่ายเรซินอัตโนมัติ

การจ่ายเรซินอัตโนมัติ

ระบบจ่ายเรซินอัตโนมัติของเราจะจ่ายเรซินขณะที่ชิ้นงานกำลังพิมพ์อยู่ Form 3L รองรับตลับเรซินสองตลับเพื่อหลีกเลี่ยงการหยุดชะงักระหว่างการพิมพ์