3D Printing Experiences Since Feb, 2013

Markforged FX20

- Home

- Shop

- 3D printer, Markforged 3D Printers

- Markforged FX20

Markforged FX20

Markforged FX20 brings the Digital Forge and Continuous Fiber Reinforcement to a new realm of parts, problems, and industries.

- Description

Description

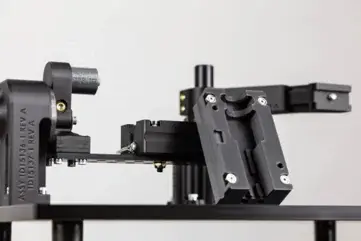

Markforged FX20 – Large-Format Industrial 3D Printing

High-performance, large-format 3D printing for advanced parts

The Markforged FX20 is a large-format 3D printer engineered for industrial use, designed to print with high-performance,

high-temperature materials. It offers large-scale precision, making it ideal for industries like aerospace and automotive.

Industrial Series

FX20

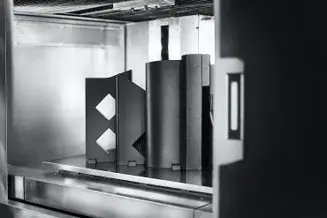

An ULTEM™ Filament capable production platform for big, strong, high temp parts — usable from factory floor to flight.

MATERIALS OVERVIEW

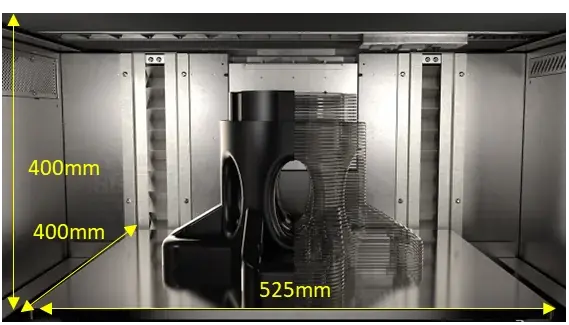

Large Model Creation

The FX20 has the largest printing area among the printers offered by Markforged. It can now create large models with dimensions of 525mm × 400mm × 400mm, allowing for greater versatility in its use.

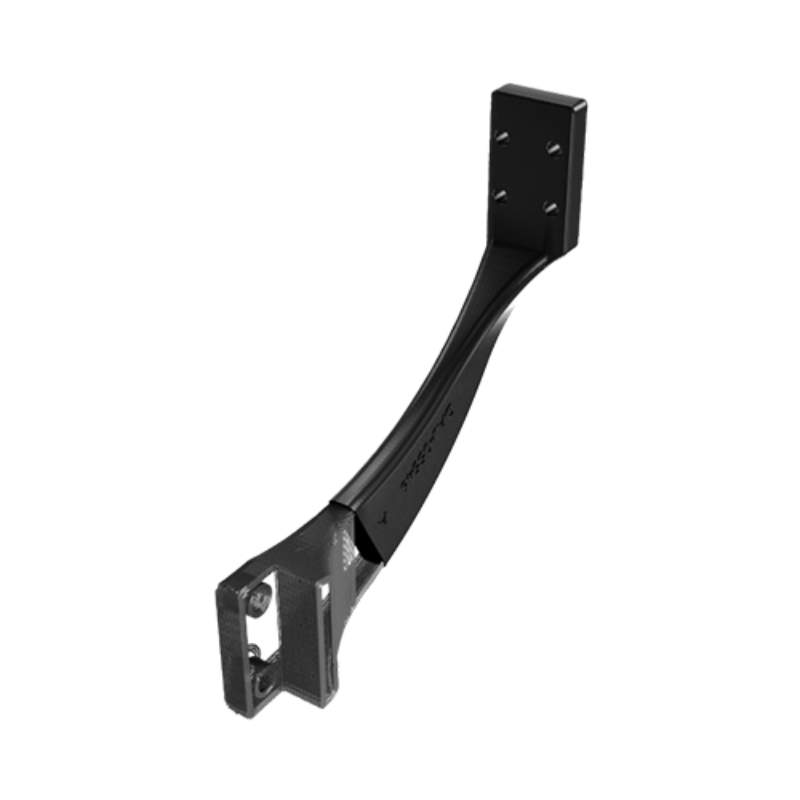

Using Long Carbon Fiber with 3D Printers

Utilize the lightweight and strong properties of carbon fiber with 3D printing. It offers high tensile and flexural strength, similar to aluminum, while being lighter. Products are expected to be lighter and stronger.

Compatible with Advanced Engineering Plastics

ULTEM™ 9085 filament is an advanced engineering plastic with excellent flame-retardant, smoke-resistant, and chemical-resistant properties. Optimized for aerospace and field applications, ULTEM™ 9085 allows Markforged to layer long fibers, opening up new application possibilities.

Printing Speed

With improvements in every part, it is now possible to print up to four times faster than the previous Desktop Series models. Even large objects can be created quickly.

3D Printers as Jig Manufacturing Machines

By utilizing carbon fiber, the objects created are highly strong and durable. They can also be used for parts that require strength and precision, such as jigs and tools in manufacturing equipment. Compared to machining MC nylon or aluminum, lead time and costs are significantly reduced.

The biggest, fastest, and most sophisticated 3D printer we’ve ever built.

Printing Process

Fused Filament Fabrication, Continuous Fiber Reinforcement

Z Layer Resolution

50 μm – 250 μm

Printing Media

Polymer Filament, Continuous Fibers

Internal Part Geometry

Closed Cell Infill with Continuous Fiber Reinforcement

Print Bed

Precision Machined Aluminum

Physical Dimensions

Width 1325 mm

Depth 900 mm

Height 1925 mm

Weight 453 kg / 1000 lbs

Build Volume

Width 525 mm

Depthth 400 mm

Height 400 mm