Pollen New Pam Series P

- Home

- Shop

- 3D printer, Pollen 3D Printers

- Pollen New Pam Series P

Pollen New Pam Series P

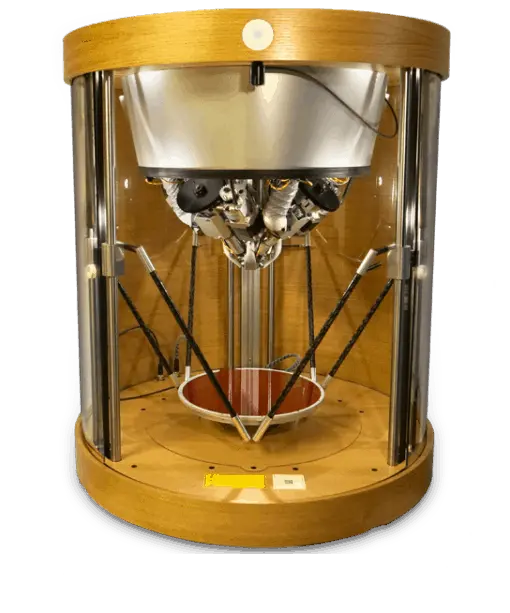

Is a high-performance 3D printer designed for industrial applications, featuring four extruders and a large print volume of Ø 300 x H 300 mm. It supports a wide range of standard thermoplastics and thermoplastic elastomers, making it versatile for various manufacturing needs. With precise stepper motor resolution, a maximum extrusion temperature of 350°C, and an advanced heated print bed, this printer delivers exceptional print quality and efficiency. It comes equipped with Honeyprint & Cura by Pollen AM software for seamless operation and optimized results.

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

Pollen New Pam Series P – Advanced Pellet 3D Printing

High-performance pellet-based 3D printer for versatility

The Pollen Pam Series P is an advanced pellet-based 3D printer designed for industrial applications.

Its powerful capabilities allow for a wide range of materials and precision, making it ideal for flexible, cost-effective manufacturing.

New Pam Series P

Polymer Additive Manufacturing

Precision Robustness Repeatability

Standard materials

& elastomers

A new level of creativity

New Pam Series P is using standard thermoplastics from all chemical companies and custom developped ones.

With 4 extruders, New Pam Seris P allows unprecedented applications: multi-material, properties combination, advanced support…

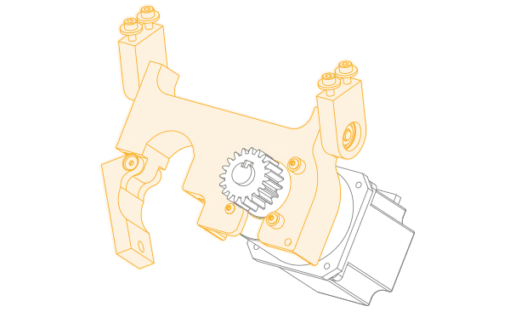

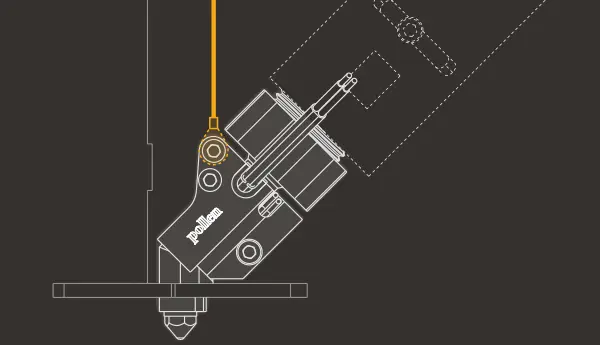

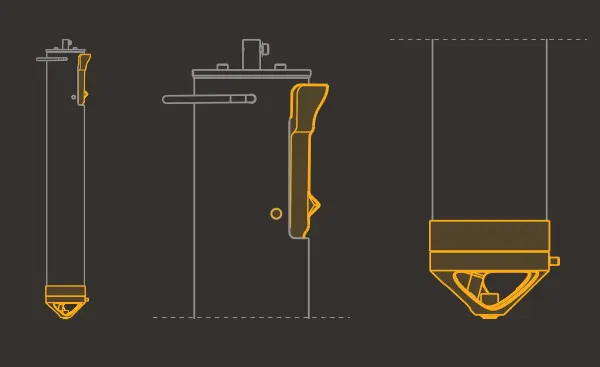

New print head

Our printhead is redesigned for better visual control

and precision. We also improved the cooling architecture.

New holding mechanism

One screw opening mechanism for easy extruder removal. Reinforced machined aluminum parts with ball bearings integration for more precision.

New lifting mechanism

All in-one stainless steel wire rope with eyelet and easy one screw removal for maintenance.

New material cartridge

Integrated cartridge opening mechanism for pellets refill on the fly. Ideal for big print jobs or to plug directly on industrial pellet feed silo.

New hopper base geometry for increased cooling performances and better pellets flow.

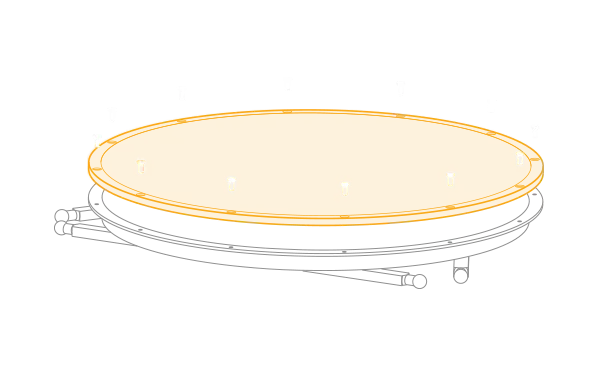

New build plate

Our build plate is redesigned for better maintenance

and dimensional accuracy.

New assembly configuration

Easy build plate replacement and micro-perforated option dedicated to materials with strong warping effect.

New carbon rods

Assembly jigs are redesigned for improved carbon rods dimensional accuracy and repeatability.

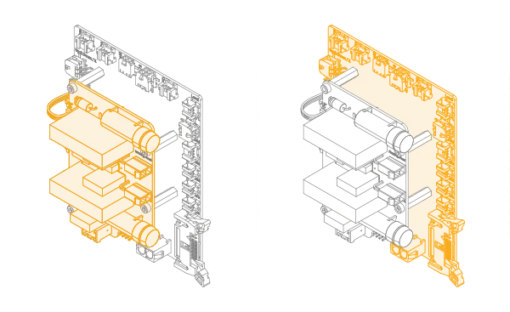

New electronics and wiring

Each extruder is controlled by two electronics boards. One is dedicated to low voltage heating elements and the second is dedicated to extra-low voltage such as motors, fans and temperatures sensors.

Pam Series P wiring is redesigned for increased robustness and printing repeatability.

Main specifications

| Property | Details |

|---|---|

| 3D Printing Process | PAM |

| Number of Extruders | 4 |

| Compatible Materials | Standard thermoplastics & Thermoplastic elastomers (Injection molding grades) |

| Print Volume | Ø 300 x H 300 mm |

| Nozzle Sizes | Ø 0.25 – 0.40 – 0.60 – 0.80 – 1.00 – 1.20 |

| Stepper Motor Resolution | 40µm (Z) and 5µm (X,Y) |

| Maximum Extrusion Temperature | 350°C |

| Maximum Print Bed Temperature | 120°C |

| Supplied Software | Honeyprint & Cura by Pollen AM |