Zortrax M300 Plus

- Home

- Shop

- 3D printer, Zortrax 3D Printers

- Zortrax M300 Plus

Zortrax M300 Plus

฿180,000.00 Inc. VAT

A Wi-Fi 3D printer with one of the biggest build volumes among Plug & Play devices.

- Large build volume (300x300x300 mm)

- Wi-Fi and Ethernet connectivity

- 3D printing farms ready

- Advanced remote management

- Filament endstop mechanism

- Built-in camera

- Intuitive LCD touchscreen

- Improved axes geometry

- Upgraded extruder

- Upgraded cooling system (double fan and extruder cooling)

- Redesigned hotend (V3)

- Redesigned nozzle with new geometry

- Compatible with semi-flexible materials

- Compatible with Z-ULTRAT

- Wide range of dedicated filaments

- External materials are applicable

- Description

Description

This post is also available in: ไทย (Thai) 日本語 (Japanese)

Print big models in one go

Zortrax M300 Plus

Zortrax M300 Plus 3D printer is designed to reliable operation in multiple long printing cycles typical for a machine of that size.

Made with high-quality components, it offers low-maintenance costs and compatibility with a wide range of filaments.

Large

workspace

Large workspace, measuring 300 x 300 x 300 mm, is enough to print big models in one go.

Wide filaments compatibility

The printer is designed to support wide range of dedicated and third-party filaments.

Built-in

camera

3D printing process can be remotely monitored through a built-in camera.

Material end detection

The printer will automatically switch into pause mode when it runs out of filament.

Advanced extruder and nozzle

An extruder with a nozzle geometry designed to support 3D printing with flex and nylon-type materials.

Intuitive interface

Zortrax M300 Plus is a Plug & Play device ready for high quality 3D printing right out of the box. The printer can be controlled via an intuitive touchscreen or remotely via Wi-Fi or Ethernet network. Automatic firmware updates introduce new functionalities and UI improvements on a regular basis.

3D printing big models in one go

Large workspace in Zortrax M300 Plus allows printing big models in one go without breaking them down into separate parts that need to be assembled. That’s particularly important when durability is of the essence as joints are usually the weakest spots in the structure.

Even 3x faster printing!

Zortrax M200 Plus can speed up printing thanks to the Speed Mode feature available in a free firmware update. Print speed can be adjusted during the ongoing printing process without having to hit the pause button.

Zortrax Speed Mode is a great option in batch production, rapid prototyping, as well as projects where models undergo further post-processing.

Applications

3D printing has been invented as a rapid prototyping technology but today it can do a whole lot more.

Zortrax FDM 3D printers work in various industries ranging from education through health care to aerospace.

Prototyping consumer products

Making consumer products takes a lot of prototyping. Zortrax M200 Plus 3D printer can make this process faster and more affordable.

Architecture modeling

Architectural scale models require millimeter precision to get the proportions right. Zortrax M200 3D printer can automate this process.

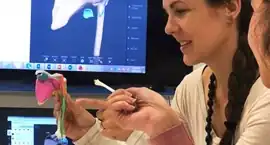

3D printed educational props

Custom made educational props are useful in anatomy courses. Zortrax M200 Plus can 3D print them at a cost well below the market price.

Large scale manufacturing

Large production plants can save up to 99% on spare parts by 3D printing them on the spot. 3D printing farms can handle it with ease.

Medical models

3D printed models can be based on CT scans. Such models are useful in facial reconstruction and planning of surgeries among others.

Aerospace engineering

NASA uses Zortrax 3D printers to prototype tools for astrounauts working onboard the International Space Station.

Making robotics easier

Building successful robots is a challenging task. With Zortrax M200 3D printer iterating through different designs becomes easy.

Automotive research and development

Modeling in clay is a usual way to make early stage concepts in the automotive industry. Former Ferrari engineers found 3D prinitng faster and more efficient.

Dimensions

Build volume : 300 x 300 x 300 mm

Material container Spool : Material diameter 1.75 mm

Nozzle diameter : 0.4 mm / 0.3 mm / 0.6 mm

Support : Mechanically removed

Extruder : Single

Extruder cooling system : Radial fan cooling

Hotend : Single, V3

Platform : Heated; perforated and glass are applicable

Material endstop : Mechanical

Connectivity : Wi-Fi, Ethernet, USB

Operating system : Android

Processor : Quad Core

Touchscreen : 4″ IPS 800 x 480

Camera : Yes

External materials : Applicable

Printing

Technology : LPD (Layer Plastic Deposition)

Layer resolution : 90-290 microns

Minimal wall thickness : 450 microns

Platform levelling : Automatic or manual

Maximum printing temperature (extruder) : 290° C

Maximum platform temperature : 105° C

Ambient operation temperature : 20-30° C

Storage temperature : 0-35° C

AC input : 110 V ~ 5.9 A 50/60 Hz ; 240 V ~ 2.5 A 50/60 Hz

Maximum power consumption : 360 W